Happy Camp is really the small-scale gold prospecting capital of America. It is a great place to be during the summer months. The area is rich with gold mining potential. Local communities are very friendly to gold prospectors. The weather is fantastic.

There were ten of us participating on this surface mining project, which included my two long-time, trusty assistants, Craig Colt and Dick Bendtzen. By surface mining, I mean prospecting for and developing gold deposits that are located outside of the active waterway. We do six 2-day (weekend) surface mining group projects and one week-long surface group mining project each season. We also do several week-long dredging projects. Everyone who participates is rewarded with an equal share of all the gold that is recovered during a project. It does not come free, though. We work hard for all the gold we recover!

Actually, how much gold we recover during the Group Mining Projects almost always comes back to how well we are able to organize ourselves into a cohesive team. All the participants on this Project showed up eager to go. Because Mary Taylor was along, I knew from the beginning that we were going to get a lot of gold! Mary is one of the most enthusiastic and dedicated gold prospectors I have ever met.

Having well over 60 miles of mining property to choose from in the Happy Camp vicinity (actually 120 miles when you count both sides of the river), we have plenty of choices where to do our surface mining projects. This time, though, we decided even before the Project that we were going to check out the far side of the river on the Club’s Wingate claim. This is located around 15 miles downstream from Happy Camp along the Klamath River. Very little has been done by members on this extensive claim over the years, mainly because a rather steep canyon separates the working-part of the claim from Highway 96. Even so, longtime members and very experienced prospectors, Rex & Earlene Kerr, had been telling us that they found a very rich gold deposit on the far side of the Wingate claim several years ago. They have since taken up dredging, so they never went back to finish cleaning up the gold. They said they were using a boat to get across the river towards the lower end of the claim.

The lesson I always try to put across to members, is that if you want to increase your chances of finding high-grade gold, do your prospecting in areas where other members have already been experiencing some success. As I know Rex & Earlene very well, when they reported finding a rich gold deposit at Wingate, I knew they were not kidding around. This is just one of the wonderful things about being associated with The New 49’ers; so many active prospectors are willing to share their success with others!

Craig Colt had the foresight to find Rex Kerr a few days before this Project and get him to go down to Wingate and show Craig exactly where he and Earlene were doing so well. So on the Saturday morning starting this Group Project, everybody was excited to go down there and get started!

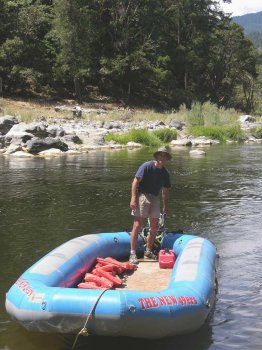

Wingate is a huge claim, with most of the workable part on the far side of the river. The first big challenge in this Project was in figuring out how we were going to get ourselves and our gear over to the other side. It didn’t take us long to figure out that a small boat can be launched at both ends of the claim. We decided to start at the top. Through some energetic teamwork, we had the boat in the water, and everybody across with sampling gear, within just a few hours.

Once on the other side with lunch behind us, while Craig and a small team hiked down to see if they could find Rex & Earlene’s old workings, several others started digging out the bedrock cracks near where we landed the boat. Just within a few minutes, Mary was already whooping it up about finding some rich gold. Leave it to Mary to make the first strike! I was amazed how big the golden flakes were! Even though Craig and a few others had already headed down that way, Mary’s strike was enough to change our plans to immediately begin trying to develop something good right near the boat landing!

Expanding upon Mary’s success, we started using bars to break open bedrock cracks upstream and downstream directly in line with Mary’s spectacular find. Almost immediately, Mary recovered another pan of large, rich golden flakes. Wow! But our additional pans further away were not turning up high-grade. So we worked our way closer towards Mary, only to discover that she had located a small single deposit. Too bad! Just for a little while there, I thought we had discovered a rich deposit that was going to carry us all the way through the week. Like a dowsing rod, Mary had zeroed in right on a small hot spot!

Just as we were figuring out that Mary’s initial deposit was just a small one, one of Craig’s helpers returned to the boat for more gear. He told us that they were already into something good further downstream. That sure lifted my spirits! So I gathered up a few more helpers and off we went to see what Craig’s team had found.

Craig’s deposit was in a bedrock trough immediately upstream from where Rex & Earlene had been mining several years before. There was a thin layer of hard-packed streambed material on top of some very uneven bedrock. Through some trial and error, we discovered that the gold was coming from off the bedrock, and also out of the hard-packed material. This was good! While the flakes were not nearly as large as what Mary had found, the gold was plentiful. We devoted the remainder of the first day spreading out Craig’s discovery to make sure the gold deposit was large enough to justify bringing in a high-banker on the following day. It was!

Dennis Taylor, Craig Colt & Dick Bendtzen

Dennis Taylor, Craig Colt & Dick Bendtzen

working the high-banker in Craig’s discovery.

All of the bedrock irregularities over there made a perfect setting to set up a high-banker (small motorized sluice) for dredging on the following day. We did this by setting up a small water pump down near the river. By pumping water up into a suction nozzle, and allowing the water to flow back into our work area, we were soon dredging the hard-packed pay-dirt up into a sluice box. We were about 50 feet away from the river. Overflow water was caught by other natural troughs in the bedrock. This was a textbook situation for surface mining!

It is important to note that while no dredging permits are required in California to dredge in areas outside of the active waterway, there are regulations which prevent you from making too large of a hole up out of the water (without special permit), and which prevent you from putting dirty water back into the active waterway. Making sure we stay within these guidelines is one of my primary duties when we do these Projects.

By the end of the second day, we had fully worked out Craig’s discovery. We recovered a healthy amount of gold from that. But the good times were over. On the morning of day-3, we found ourselves sampling again. Deciding that we should check it out, we spent the first half of the 3rd

day sampling the upper-end of Wingate on the highway-side of the river. Preliminary sampling results looked pretty good. But the deposit over there seemed pretty spotty to me, and I was concerned to not lose a whole day or two trying to recover gold out of a lower-grade deposit, when we might still find something better further downstream. We always debate these tough decisions during the Projects, so everyone is able to take part in the process which evolves into the final result. After some discussion about our options, we split the sampling team in half, and I used the boat to place several samplers on the far side of the river towards the bottom-end of the claim. This took some creative boat work by Craig and me. We had to portage our small aluminum boat through a fairly bad set of rapids. But through some trial and error, we worked out a way to get the boat through the rapids in both directions without too much difficulty. Boating to the lower area of the claim was a heck of a lot easier than hiking down there!

Dennis Hoepfer helping to sample the lower-end of Wingate.

Dennis Hoepfer helping to sample the lower-end of Wingate.

Down towards the lower-end of the claim, we started pulling excellent pans out of the exposed bedrock cracks right away. It didn’t take us long to discover a rich section of bedrock that was about 50 feet wide, starting about 30 feet from the active river. Most of it was exposed bedrock that had small pockets of hard-packed streambed which were loaded with fine gold. This place looked good! So during the afternoon of the 3rd day, we found ourselves relocating the whole team down to the lower end, with multiple vack-mining machines. Our mission was to discover if this deposit was worth working on the following day with the high-banker. It was!

But rather than use the high-banker, the morning of the 4th day found our whole team working together to create a mini-high-banker using a Le’ Trap sluice with a special feed from two garden hoses. The problem with this new high-grade area was that, while plentiful, most of the gold was very small in size. We could not produce enough material with the vacks to feed a normal high-banker. Because the Le’ Trap sluice recovers fine gold exceptionally well, we came up with an idea to make a special water feed so we could process material from the vacks way up out of the water. The system worked great!

Mary Taylor & TaTiana Serbanescu working the cracks in the hot new area.

We devoted most of the 4th and 5th days to production mining with the vacks. We all took shifts at running the machines, breaking open cracks, filling buckets, screening the pay-dirt through an 8-mesh screen and feeding the Le’ Trap recovery system. While mostly fine in size, by the end of the 5th day, there was a lot of gold adding up in our bucket!

We don’t do a final gold clean-up every day during these Projects. The process takes too long. So we allow our gold concentrates to add up in a bucket until the last day. Then we clean it up all at once and split it off. But we do pay close attention to how much gold is present from each sample – or each production day. This gold was so fine and plentiful, that the concentrates were looking very rich. We were going to have a good week!

On the morning of day-6, Dick told me he was getting a very strong feeling about an area just downstream from where Rex & Earlene had made their big strike. So he decided to hike up there and do a few samples. It was quite a ways up there; but about an hour later, I thought I could see Dick waving his arms around. So I drove the boat over there to have a look. Sure enough, Dick had made the richest strike of the week! It was under about 2 feet of hard-packed streambed on bedrock. The whole area had been buried under about 6 inches of loose sand. That was the reason we missed it the first time we were sampling around there. Dick’s samples were producing large flakes and small nuggets. It was truly a rich find! This is not the first time Dick has discovered the big strike of the week. We are sure lucky to have him on these projects!

On the morning of day-6, Dick told me he was getting a very strong feeling about an area just downstream from where Rex & Earlene had made their big strike. So he decided to hike up there and do a few samples. It was quite a ways up there; but about an hour later, I thought I could see Dick waving his arms around. So I drove the boat over there to have a look. Sure enough, Dick had made the richest strike of the week! It was under about 2 feet of hard-packed streambed on bedrock. The whole area had been buried under about 6 inches of loose sand. That was the reason we missed it the first time we were sampling around there. Dick’s samples were producing large flakes and small nuggets. It was truly a rich find! This is not the first time Dick has discovered the big strike of the week. We are sure lucky to have him on these projects!

With only about a half-day remaining, we immediately mobilized a major move from the fine gold deposit we were working further downstream, with multiple boatloads of gear and people. By lunchtime on the 6th day, we were high-bank dredging in Dick’s new discovery. This was a different kind of mining altogether from what we had been doing the previous 2 days. Although adjusting to the change did not require much direction on my part. Everyone there had plenty of experience by then. We all just stepped in to do what was needed. With only a half-day remaining, we wanted to clean-up as much of Dick’s deposit as we could. We took turns operating the dredge, while also filling buckets with material and feeding the high-banker to achieve as much production as we could. My main focus remained on filling our excavation behind us, to never allow our open hole to become very large. I was also making sure that no dirty water ever got back into the river from our high-banker.

By the end of the 6th day, we had a good showing of larger-sized gold to go along with all the fines we had accumulated earlier in the week.

By the end of the 6th day, we had a good showing of larger-sized gold to go along with all the fines we had accumulated earlier in the week.

Everyone was working as a team to operate the high-banker on the last day. We wanted as many nuggets as we could get!

Normally, we use the 7th day to pull all our gear off the river and put it all away. We also do the full final clean-up process. Everyone participates in every step of this. Over the many years, we have worked out a system of final clean-up that retains all of the gold without the use of any mercury or other chemicals. This involves the use of a Gold Extractor – which is like a miniature sluice with very low-profile riffles. When set up properly, this device will work all of your concentrates down to all of your gold with no loss whatsoever, along with only about a tablespoon of black sands remaining. Then this final material can be dried and run through a set of final clean-up screens. Once separated into different size-fractions, it is very easy to separate the gold from the last of the impurities. We mainly do this by blowing off the impurities, which are about 4 times lighter than the gold.

Phil Maher & Sara Rese showing off some project gold!

At the end of the 7th day, we split off the shares of the gold evenly between all the participants. Everyone was excited to get their share. We then took a moment to review our week and discuss the things that we did, and the decisions that we made along the way, which led us into our good fortune. Sampling is an interesting process whereby every key decision you make is like a crossroads that will directly affect the final outcome. Each time we do one of these projects, we come to the very same conclusion that you should never give up hope; that if you just stick with the process, you will always get right into the next gold deposit.

At the end of the 7th day, we split off the shares of the gold evenly between all the participants. Everyone was excited to get their share. We then took a moment to review our week and discuss the things that we did, and the decisions that we made along the way, which led us into our good fortune. Sampling is an interesting process whereby every key decision you make is like a crossroads that will directly affect the final outcome. Each time we do one of these projects, we come to the very same conclusion that you should never give up hope; that if you just stick with the process, you will always get right into the next gold deposit.

This story is dedicated to Mary Taylor, who is one of the most enthusiastic and dedicated gold prospectors that I have ever met. Mary will always be a welcome participant on any of the group mining projects that we organize!

This story is dedicated to Mary Taylor, who is one of the most enthusiastic and dedicated gold prospectors that I have ever met. Mary will always be a welcome participant on any of the group mining projects that we organize! The next day, Jake and Lily told me that they had already crossed the river with gold pans to check out the area. They told me that the whole bar on the other side appeared to consist of

The next day, Jake and Lily told me that they had already crossed the river with gold pans to check out the area. They told me that the whole bar on the other side appeared to consist of

As is usually the case, my long-time, very experienced assistants, Craig Colt and Dick Bendtzen, were participating on this project. Under normal circumstances, they do a lot of the work in the early stages of

As is usually the case, my long-time, very experienced assistants, Craig Colt and Dick Bendtzen, were participating on this project. Under normal circumstances, they do a lot of the work in the early stages of