By Dave McCracken

Suction mining underwater without a “dredge!”

Important note: Since writing this article, over the period of a year, the State of California has adopted new regulations which no longer allow any type of vacuum or suction to excavate material off the bottom of a waterway. Therefore, the underwater suction gravel transfer systems outlined here will no longer be allowed until we overcome the suction dredge moratorium. It is for this reason, we have now switched over to underwater blow mining.

Let me begin this by informing you that I am not a licensed attorney. Therefore, I am prohibited by law from providing legal advice. So the material here should just be taken as my own opinion based upon the factual material which I will present to you. You guys are free to form your own opinions and take responsibility for your own actions. Having said that, I will also inform you that our attorney has reviewed the following explanation and agrees that government officials are bound by the very language that they enforce upon us – and that my reasoning here is sound.

This discussion began on our Internet Forum where I announced that we have recently acquired the richest dredging claim along the Klamath River near Happy Camp, which will also provide some fantastic surface and underwater crevicing opportunities because of the gentle slope of exposed bedrock which is extending off the side of the river where the gold path is located.

We have actually acquired several very rich properties, but I will save that for the coming newsletters.

In my announcement, I pointed out that there is nothing in California’s dredging moratorium that prevents us from crevicing underwater using a motorized hookah air system, or even using a water pressure system to help blow gravel out of cracks. The question I posed to our forum members is how to get the gold up and into a catch container without using a suction dredge.

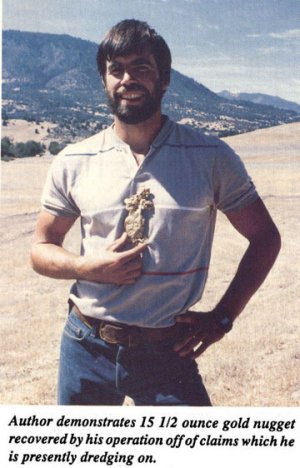

It would be one thing if we were just uncovering an occasional gold nugget or two. We would simply free those up with some hand tools and pick them out with a set of tweezers. But I have seen crevices on this particular mining claim that were loaded with a zillion pieces of gold, much of it in fines and flakes. You pretty much have to suck that up, or you will be there all year with a pair of tweezers! The original claim owners were recovering six and seven-ounce days (sometimes more) in places along this claim. They were only in there a few years before they retired. Since they operated an 8-inch dredge, they remained on the lower, slower portion of the claim. There is at least a half-mile stretch of faster, shallower water on the upper portion of the claim that, to my knowledge, has never even been sampled. This is the area I believe will make for good above and below water crevicing.

In response to my question, one of our more informed members sent me a copy of the California Department of Fish & Game’s (DFG) current suction dredge regulations which clearly state that “A person is suction dredging as defined when all of the following components are working together: (A) a hose which vacuums sediment from a river stream or lake; and (B) A motorized pump; and (C) A sluice box.” The regulations further state, “Every person who operates the suction nozzle of any suction dredge shall have a suction dredge permit in his or her immediate possession.” These regulations are current now, having been formally adopted in California on April 27, 2012.

The existing moratorium in California prevents DFG from issuing suction dredge permits. We are strenuously challenging the moratorium in several jurisdictions. Until our challenges are resolved, it is unlikely that we can operate suction dredges as defined by the regulations without being cited. Since most of us don’t want to be in trouble with the authorities, we have been doing our dredging in southern Oregon for the past few seasons.

But looking closer at the California regulations, there does remain a way for us to go down on the bottom of California’s waterways and suction up the shallower, higher-grade gravels. This is because, as defined by DFG’s own formal regulations, as long as we remove the sluice box from our motorized suction system, we are not operating a “suction dredge.” Said another way, there is an opportunity to use a motorized suction system to transfer high-grade gravel from one place in the river or creek to another location where the gravel can be more-easily processed in a separate system.

I am in possession of written communication from a high ranking DFG official, the very person who was in charge of developing the current regulations, which acknowledges that underwater suction-powered gravel transfer would not be considered “suction dredging” as long as the sluice box is removed from the system. He also cautioned that there are water quality concerns and also streambed alteration considerations. So there would be some limits involved. I’ll discuss these more in a minute.

For now, let’s just get back to my original discussion about using a hookah and motorized pumping system to expose and recover gold from very shallow deposits out in the river. I’m not talking about shallow water. I am talking about shallow material on top of underwater gold deposits.

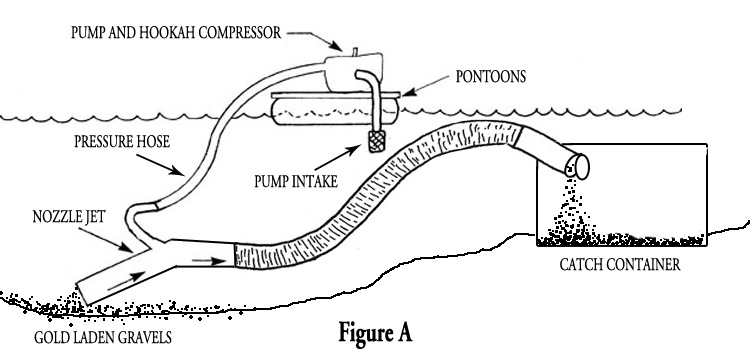

Here is just one of several ideas: Please see Figure A above. If I completely remove the sluice box from my 5-inch dredge, I am left with a floatation system which supports twin 6.5 HP Honda motors and pumps with a hookah compressor. I could use a single motor & pump with compressor to power a 3-inch Hydro-Force nozzle jet. This special nozzle will allow me the option to blow off lighter gravel to expose cobbles, which I can then move out of the way by hand. This will allow me to work my way down to the pay-dirt without having to suck up any gravel. Once I expose the pay-dirt, the Hydro-Force nozzle will allow me to suck it up and transfer it over to a catch container in shallower, slower water which is closer to the bank. Or for that matter, I could just drop it in a small pile in the shallower water along the edge of the river.

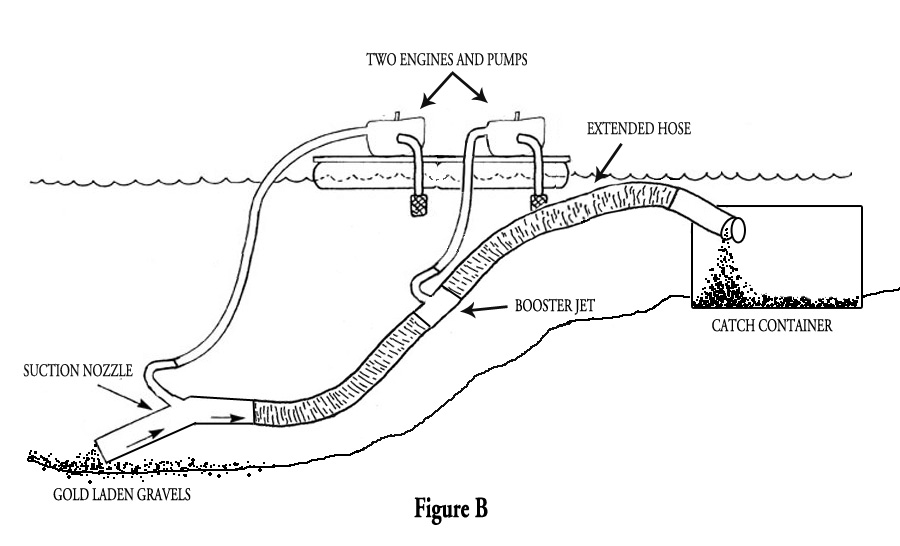

If there is some distance involved between where I am prospecting and my catch container, I can use my second engine & pump to provide power to a booster jet attached to a second 3-inch hose (See Figure B). Since the whole suction system would be underwater, I’m guessing that would give me a reach of fifty feet or more.

The catch container would need to be large enough to accumulate the amount of pay-dirt that I would suck up on a single dive. My suggestion would be to fabricate a baffle on the feed into the container so the material would be deposited there neatly.

If you make smart use of the blower function on the Hydro-Force nozzle, you can really minimize the amount of gravel that you transfer by suction to the catch container; perhaps so little that you could work it all down and recover your gold between dives with just a classification screen and gold pan!

If there is more non-gold bearing material present than you can blow off with the Hydro-Force nozzle, you would always have the option of sucking that off separately and depositing it outside of your catch container.

Several experienced prospectors I have spoken to about this had other ideas. One suggested fabricating the catch container between the pontoons on his floating platform. Then he could just float it over closer to the bank to pan the material after each dive. Another who has already experimented with the idea says he successfully attached a 20-foot piece of PVC plastic tubing to direct the discharge into a catch container that was sitting up on the streambank. This took place in the fall of 2012. He was visited by local game wardens while doing the activity. And while they expressed reservations (“sure looks like a dredge”), he was not cited and the wardens did not return.

While I’m sure we will learn more as we gain experience, here are a few of my own thoughts on “underwater suction gravel transfer systems:”

1) Make certain to not have the sluice box from your original “suction dredge” anywhere in the vicinity of the program. DFG regulations prevent you from having a “dredge” within 100 yards of any active waterway. Therefore, that third component (sluice) should not be sitting up on the streambank or even in the back of your pickup truck, even if you are not using it. Leave it at home!

2) Do not direct the discharge of your suction system into some other type of recovery system that uses a sluice. Using any sluice in combination with the suction system, all working at the same time, would likely meet the definition of a “dredge” in the regulations.

3) There has been some suggestion that even sluicing the recovered gravels at some later time would fulfill the definition of a dredge. You guys can make your own decisions about this, but I’m not buying the theory. The language in the regulation defines the three components working together. So it would seem reasonable that you could shut your underwater suction transfer system down and then separately process the gravel in any normal way that does not violate water quality standards. Though I would not be using the sluice that I took off my suction dredge, or any sluice which could be attached to the suction system. Be advised, though, that as soon as you have any sluice as part of your program within 100 yards of the suction system, you will be on thinner ground. Personally, I am inclined to be careful about sucking up a lower volume of only the highest-grade material and use a gold pan to work that down between dives (more on this below).

4) I would not suck a bunch of silty material into a catch container that is sitting in dead water alongside the bank. That might provoke water quality concerns. This is why I suggest using the blowing option on the Hydro-Force nozzle to first free up material out under the moving water. Gold is heavy. It won’t blow away if you pay attention to what you are doing.

5) I also would not advise using this system to make large excavations out in the creek or river. That might provoke streambed alteration concerns. I would use this method to work shallow deposits much the way we do in high-banking. Having said that, it has also been pointed out that the existing suction dredge regulations clearly state that there would be no requirement for a stream alteration permit, and there would be no deleterious impact upon fish, from the use of 4-inch suction dredges in California’s waterways. So it would be pretty unreasonable for DFG to make a stream alteration argument if you are careful about not making large excavations.

6) I would advise the use of riged pressure hose between the pump and nozzle jet on this type of system. It is difficult enough to keep the kinks out of lay flat pressure hose outside of the waterway.

7) Since initially, DFG wardens may not be aware of their own formal definition of a “dredge,” I suggest you print out at least the first page or two of the regulations which include the formal definition of a “dredge,” and have them available if and when any officials come around to see what you are up to. Make sure to point out the complete absence of a sluice on your suction system. And whatever you do, never refer to this activity as “dredging.” Because it is not dredging! It is an underwater suction system used to direct small volumes of high-grade material into a catch container. Nothing more. If you tell the warden you are “dredging without a sluice box,” you will probably provoke a citation, the warden telling you to explain it to the judge!

8) If any citations are written for this non-dredging underwater form of prospecting, please get in touch with us without delay. We will likely want to become involved with your defense.

Conclusion: I can process material through a “suction dredge” about as fast as anyone I know. Yet, my tailings don’t amount to much at the end of my dives. This is because most of the underwater work has to do with freeing and moving oversized material out of the way (rocks that are too big to suck up). Depending upon the size of the suction nozzle, perhaps as much as 95% or more of the volume has to do with rolling rocks behind me. I would normally suck up the other 5% of material into my sluice box if I were “dredging.” That volume over my sluice box gives me a substantial amount of heavy concentrates to process – which takes quite a bit of time.

But with this underwater gravel transfer system, I can easily visualize how I can blow the lighter material out of my way and only suck up the pay-dirt. This would dramatically reduce the amount of material I will need to process out of my catch container. While the underwater process may not be as fast or efficient as “dredging,” I might make up for it by having fewer concentrates to process.

Please note my words in bold just above. They are perhaps the most important words I have said here. This is because if you suck everything into your catch container, it will soon fill up with low-grade material which may not be worth the time to process further! The whole idea in this new system is to get the low-grade material out of your way, and only suck up the very small volume which is directly associated with the gold deposit. Gold deposits are nearly always located in a contact zone. This means either on the bedrock, between storm layers, or on top of the upper layer of hard-pack. There is an entire education about this in the articles at this link. If you still need help understanding this, you should attend one of our weekend group mining projects and allow us to show you exactly what you are looking for!

Using this system to discriminate carefully about what you suck up will accomplish two important objectives:

A) You won’t find yourself up on the bank most of the day panning a bunch of gravel that doesn’t have much gold in it.

B) You will only use the suction system to recover a very small volume of material – only that which contains the gold. A small volume tool to help with your crevicing program will give our enemies less to complain about.

I thought you guys might be interested in an official position. There has been quite a lot of debate about this “underwater suction gravel transfer” idea on the GPAA forum since I have gone public with it; and finally, someone asked Mark Stopher of DFG for the straight scoop:

Here are the official answers (2 January 2013):

“I carefully read (today) the information that McCracken provides on his website. I believe Dave McCracken’s description of the legal requirements and application of the regulations is accurate. If practiced as he describes, this is not a violation of the moratorium and is not prohibited.

There is no specific permit required and no seasonal restrictions. Since this is not suction dredging, neither the moratorium or our adopted regulations for suction dredging apply. It’s essentially a loophole in existing law. However, as McCracken notes, Fish and Game Code section 1602 could apply if the streambed alteration is substantial, that is, you create a big hole. My guess is that such a system will be less efficient, and less excavation will occur, than if you were using a suction dredge since there is no sluice box and miners will need to use some other system to sort through the material.”

Mark Stopher

Habitat Conservation Program Manager

California Department of Fish and Game

601 Locust Street

Redding, CA 96001

voice 530.225.2275

fax 530.225.2391

cell 530.945.1344

Underwater Mining Seasons on New 49’er Properties: Underwater suction mining without the use of a “dredge” is allowed on our Klamath River properties between the Scott and Salmon Rivers on a year-round basis, and up the Klamath from its confluence with the Scott from the 4th Saturday in May through September 30. Underwater suction mining is permitted along our creek properties and the Scott River from July 1 to September 30. Underwater suction mining is permitted on the Salmon River from July 1 through September 15.

This new idea will at least allow us access to some of the submerged gold deposits that otherwise would be out of our reach until the “dredge” moratorium is lifted in California. How’s that for good news?

It starts getting pretty hot out on the bar by about noon. So that’s normally about the time we are shutting things down and going into our final clean-up stages. By “

It starts getting pretty hot out on the bar by about noon. So that’s normally about the time we are shutting things down and going into our final clean-up stages. By “

Please

Please

We believe that the future of small-scale prospecting could largely depend upon how effectively we as an industry pull together in a responsible way to meet the challenges which we will face together. Much of this effectiveness and dedication is contingent upon gaining exposure to existing operations which are already effective. This is because, generally, the more skilled you are as a gold prospector, the better your chances of realizing your expectations, ambitions, and goals. Moreover, it is generally true that if you are successful, you radiate your success to others and our entire industry flourishes and grows.

We believe that the future of small-scale prospecting could largely depend upon how effectively we as an industry pull together in a responsible way to meet the challenges which we will face together. Much of this effectiveness and dedication is contingent upon gaining exposure to existing operations which are already effective. This is because, generally, the more skilled you are as a gold prospector, the better your chances of realizing your expectations, ambitions, and goals. Moreover, it is generally true that if you are successful, you radiate your success to others and our entire industry flourishes and grows.

The New 49’ers provide all of the dredges, motorized sluicing equipment and boats used in these projects. Participants will need to have their own wet-suits (for those who will dredge) or other protective clothing and footwear, a dive mask and transportation. Participants provide their own lodging and nourishment.

The New 49’ers provide all of the dredges, motorized sluicing equipment and boats used in these projects. Participants will need to have their own wet-suits (for those who will dredge) or other protective clothing and footwear, a dive mask and transportation. Participants provide their own lodging and nourishment.

Most intermediate and larger-sized gold dredges come with built-in hookah-air systems. These attach to the same engine that powers the water pump. As demonstrated in the following video segment, air for breathing underwater is generated by an air compressor, passes down through an air line, and provides air to a diver through a regulator, similar to what is used by SCUBA divers:

Most intermediate and larger-sized gold dredges come with built-in hookah-air systems. These attach to the same engine that powers the water pump. As demonstrated in the following video segment, air for breathing underwater is generated by an air compressor, passes down through an air line, and provides air to a diver through a regulator, similar to what is used by SCUBA divers: The

The

A cutter-head will just get bogged down (and damaged) in a normal

A cutter-head will just get bogged down (and damaged) in a normal  If you want to do serious excavations with a suction dredge, you must leave the opening of the suction-nozzle as large in diameter as possible, while still reducing it enough to eliminate un-necessary

If you want to do serious excavations with a suction dredge, you must leave the opening of the suction-nozzle as large in diameter as possible, while still reducing it enough to eliminate un-necessary

A gold-dredger has an advantage, in that he or she is able to float equipment where he or she wants it to go, sucking up gravel (sampling) from various strategic areas. This is much easier than having to carry equipment around and set it up in each new area, as is required in conventional mining.

A gold-dredger has an advantage, in that he or she is able to float equipment where he or she wants it to go, sucking up gravel (sampling) from various strategic areas. This is much easier than having to carry equipment around and set it up in each new area, as is required in conventional mining. In fact, most of the work associated with suction dredging involves the organization and movement of cobbles and (sometimes)

In fact, most of the work associated with suction dredging involves the organization and movement of cobbles and (sometimes)

Some have said that the pen is mightier than the sword, and I am sure that on occasions this has truly been the case. Throughout the ages, man has used words to explain, convince and cajole his fellows about one thing or another. Advertising executives are no exception to the rule; and in their deft hands, a word can become downright dangerous or at least costly to some of us. I am, of course, speaking about the use of the language without explaining the meaning of the terms used.

Some have said that the pen is mightier than the sword, and I am sure that on occasions this has truly been the case. Throughout the ages, man has used words to explain, convince and cajole his fellows about one thing or another. Advertising executives are no exception to the rule; and in their deft hands, a word can become downright dangerous or at least costly to some of us. I am, of course, speaking about the use of the language without explaining the meaning of the terms used. But with the advent of meter identification on many detectors, the user was no-longer locked into searching in a discriminate mode with limited depth. He or she could finally search in an all-metal mode if desired and check the meter for probability of target identification. This is where the definition of terms is becoming important and what I have been leading up to. I have recently heard it said that this or that detector is better for prospecting because it doesn’t discriminate, and many a treasure hunter has set aside his or her perfectly good multipurpose unit and bought another unit just for prospecting. I am not suggesting that these new units are not worthy of the task; but in many instances, it was costly and unnecessary to buy two units. First of all, the original unit should be able to cancel the ground effectively; and secondly, the owner must learn the skills necessary to operate it in a prospecting environment. Every company makes such units, and all are capable of finding the elusive gold nugget. The meter should work independently of the all-metal audio signal. That is, you should be able to operate the detector in the all-metal mode and hear every target that the loop passes over. The meter should respond to these targets in some sort of predictable fashion.

But with the advent of meter identification on many detectors, the user was no-longer locked into searching in a discriminate mode with limited depth. He or she could finally search in an all-metal mode if desired and check the meter for probability of target identification. This is where the definition of terms is becoming important and what I have been leading up to. I have recently heard it said that this or that detector is better for prospecting because it doesn’t discriminate, and many a treasure hunter has set aside his or her perfectly good multipurpose unit and bought another unit just for prospecting. I am not suggesting that these new units are not worthy of the task; but in many instances, it was costly and unnecessary to buy two units. First of all, the original unit should be able to cancel the ground effectively; and secondly, the owner must learn the skills necessary to operate it in a prospecting environment. Every company makes such units, and all are capable of finding the elusive gold nugget. The meter should work independently of the all-metal audio signal. That is, you should be able to operate the detector in the all-metal mode and hear every target that the loop passes over. The meter should respond to these targets in some sort of predictable fashion.

Running a successful mining operation is one thing. Helping someone else to be able to run a successful operation is something else altogether. During the past several years, we have

Running a successful mining operation is one thing. Helping someone else to be able to run a successful operation is something else altogether. During the past several years, we have  I personally know a fair number of successful gold miners; some who we worked with and some who learned on their own. Some are successful on a smaller-scale. Some mine gold to support themselves and their families.

I personally know a fair number of successful gold miners; some who we worked with and some who learned on their own. Some are successful on a smaller-scale. Some mine gold to support themselves and their families. One of the primary common denominators I recognize being present in successful miners alike is a never-ending drive, or hunger, or urge to get on and stay on the

One of the primary common denominators I recognize being present in successful miners alike is a never-ending drive, or hunger, or urge to get on and stay on the  I’m focused on being the world’s best underwater mining specialist–and on helping others, also, to be very good at it.

I’m focused on being the world’s best underwater mining specialist–and on helping others, also, to be very good at it. Successful people win their games by focusing themselves towards accomplishment within the rules of the game. Don’t like the rules? Do something effective to bring about agreement to have the rules changed. Winning the game by the rules brings great satisfaction, and successful people are willing to put out the necessary effort to gain each step along the way. Sure, it’s always a bit more difficult to not take the unethical short cuts which present themselves. But real progress is built upon a solid foundation of the ability to accomplish.

Successful people win their games by focusing themselves towards accomplishment within the rules of the game. Don’t like the rules? Do something effective to bring about agreement to have the rules changed. Winning the game by the rules brings great satisfaction, and successful people are willing to put out the necessary effort to gain each step along the way. Sure, it’s always a bit more difficult to not take the unethical short cuts which present themselves. But real progress is built upon a solid foundation of the ability to accomplish.