BY TOM BRYANT

Helpful Tips on Dealing with Big Rocks Underwater

Every experienced dredger has had at least one close call with a rock that decided to ruin his (or her) day, despite the precautions he was, or thought he was using. It comes with the territory. Just like a close call in traffic, you have a while of silent thankful prayer vowing to never let that happen to you again, and then you get on with things like nothing ever happened.

If you have ever been trapped by a boulder while dredging, and are still alive to tell about it, then you will likely have a tale to tell that would make people sit up and listen.

For those of you that have never experienced it, let me try to tell you what it is like:

There is no noise, and very rarely is there any warning. A horrible, crushing weight comes down on you, like “Jaws,” and you get a sick feeling in the pit of your stomach as you instinctively try to pull yourself free. You try to tell yourself to keep calm, but the shock of the pain as the boulder crushes your leg or arm, joined with the realization that you have very few escape-options, makes you hyperventilate. You cannot seem to get enough air through your hookah regulator.

If your airline is also pinned under the rock, you might find yourself with no air at all! You try to pull yourself free, but there is no place to push against; and the rock is not moving. If you have not already drowned by now, or been so badly hurt that you can no longer function; reason will slowly return, and you will start thinking hard about what your resources are and what remaining options you have. “How much gas do I have left?” “Am I caught, or is a piece of my equipment caught?” “Can I use the dredge to suck away a channel to free myself?” “Where the heck is my diving partner?”

The biggest danger facing the trapped diver is time. How long until the air runs out? Your whole life is tied to your hookah airline and the dredge motor. This is a good reason to take suction dredging on with the right approach in the first place, making sure to keep all your dredging gear in a good state of maintenance and repair.

A trapped diver needs time. As long as he has air and has not sustained a fatal injury from the accident, he can wait it out underwater until he starves to death. Here follow some good ideas when you find yourself dredging around big rocks. Some of these ideas will buy you time. Some will help you avoid serious problems in the first place. Some will help get you out of trouble if you are having a bad day:

A trapped diver needs time. As long as he has air and has not sustained a fatal injury from the accident, he can wait it out underwater until he starves to death. Here follow some good ideas when you find yourself dredging around big rocks. Some of these ideas will buy you time. Some will help you avoid serious problems in the first place. Some will help get you out of trouble if you are having a bad day:

1) It is always a good idea to work with a buddy.

2) Your buddy should have a source of air. If you are dredging in water that is too deep for your buddy to stand waist deep, how else can the person stay underwater to help you? This could involve an extra hookah line on the dredge and/or even a scuba tank with regulator which is ready to go in the event of an emergency.

3) Unless your buddy is the incredible hulk, you should have the basic tools for moving large rocks. At the very least, a long pry bar and a few wedges. Few people realize the great advantage that a wedge can provide. Wood and plastic wedges can sometimes be hard to use underwater, because they try to float away. I suggest having a metal wedge or two on the dredge site.

The difference between freedom and drowning can be a fraction of an inch. A wedge, hammered alongside a diver’s trapped limb, could lift or move the rock just enough for the person to break loose. A wedge can be used to prop-up the rock as you try to dredge some material away to create more room under the boulder. A wedge can be used to create a pivot-point for your pry bar. I have even heard that a wedge was used once to break-up a large rock that had trapped a gold miner. This was on dry land, but it would work underwater, as well.

4) Never leave a large rock above you in the open working face of a dredge excavation. This is a rule Dave McCracken promotes in his books and videos; it is one of the best safety tips that you can have. As long as that rock is up there hanging over you, it can work loose and do you harm. If you expose a large rock in your working face, and you do not have the ability to winch it out, then you will have to drop back and clear some bedrock where you will place it in the back of your dredge hole. Then you can dredge away material so that the rock will roll down the face of the cut and end up back in your previously-dredged hole. Follow number 5 when cutting this rock out.

5) If you must dredge away material from around a large rock that has the potential to move, then work from above the rock if possible. This can be awkward; but if you can float on the surface and move material away, you know the rock will fall down away from you. If you are above it, the rock cannot swim up and get you. Put one hand on the rock as you work around it. If that thing even moves a hair, you can feel it and will have a better chance of moving back out of range. If you have to move, move fast upwards and downstream letting the current help carry you out of range. The rock will be going forward and down. Drop the dredge nozzle! Trapped dredge nozzles cannot drown, but they can anchor a diver that is trying to get clear of danger. Keep in mind that you should not have any section of the dredge hose over or across your body when working around big rocks.

6) If you are working a cloudy hole, and you expose the large face of rock, let the water clear so you can get a good look at the thing. Alert any other divers in the hole with you to a possible dangerous rock! You might not get caught by a falling boulder, but your cobble-man further down the cut might get caught.

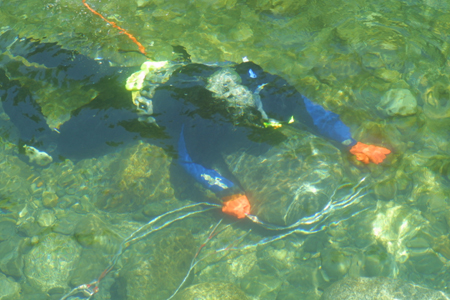

7) Rig up an emergency signal with your buddy up top. There are all sorts of ingenious setups for controlling the throttle on the dredge from the dredge nozzle. This is a practice which I personally believe is detrimental to fine gold recovery as a rule, but that is another article altogether. It would not be difficult to rig up an electronic or mechanical alarm system to alert someone topside. Tugging on your air hose is a common signal sys- tem, but is impractical if your buddy isn’t holding onto the hose or in view of it at all times. I have seen floating buoy systems used that do have a potential, as long as you can reach it in an emergency. It is good practice for the top-side person to put on a mask and snorkel every once in a while to check on the dredger.

8) When winching a rock, never stay near it, especially lower in the hole than it is. Sometimes a pry bar is needed to help move the rock while winching. This is a dangerous practice. But if you think you have no other choice, then try to stay above the rock while prying. Do not winch or pry blind. Keep your eyes on that rock. If it shifts in any manner whatsoever in a way you didn’t expect, back off and wait for it to settle.

8) When winching a rock, never stay near it, especially lower in the hole than it is. Sometimes a pry bar is needed to help move the rock while winching. This is a dangerous practice. But if you think you have no other choice, then try to stay above the rock while prying. Do not winch or pry blind. Keep your eyes on that rock. If it shifts in any manner whatsoever in a way you didn’t expect, back off and wait for it to settle.

9) Sometimes a dredger will expose a section of a large rock and feel it is too risky to work around until later, when the hole is clearer or whatever. This is good common sense; but if you are in fast water, keep in mind that by exposing a portion of the rock, you have opened it up for increased erosion. You have also removed some of the structure that was holding the rock in place. The fast current could eat away the critical portion of the gravel you left to hold the rock up. If you turn your back on the rock, you could be wearing it! Always treat an exposed rock like a loaded gun. Keep your eyes on it, and unload it as soon as possible by moving it safely or working around it in such a way that it will not come down on you.

10) Never try to prop up a boulder and work under it. I have seen where a diver will dredge out sections of gravel from under a large rock, and then stick a cobble under the rock so it won’t drop as he continues to dredge away more of the supporting material. It is better to dredge a ramp down into your cut that you can roll the boulder down or winch it into. Propping boulders was a specialty of the Chinese miners in the old days, but even they lost sometimes. And, they weren’t working underwater while they took risks. The added risk is just not worth it.

11) Quite often, when working with a large dredge in shallow gravel on bedrock, a dredger will just rest the nozzle on the rock and let the face of gravel cave in and flow to the nozzle. It is easy to get so involved in watching the material flowing into the intake and trying to keep large cobbles from flowing onto the nozzle that you forget to look up at the face you are working. A large boulder stuck part way up the face can be exposed and drop in on you as you dredge away its support. Always watch the full face of your cut.

12) In some deep dredging operations, lift bags or 45-gallon drums are used to lift rocks and float them downstream out of your excavation. A 45-gallon drum is common because of the low cost. One end is cut out and cables are strung down from the open-end. When moving a rock, the drum is filled with water and allowed to sink down to the rock. The cables are attached and the drum is set up so the closed-end faces the surface. Air from an extra hookah rig is fed into the drum, and the lift created by the air-filled drum lifts the rock and floats it downstream.

It sounds easy; but in practice, it can be a lot harder than it reads. An air-filled drum will lift at least 300 lbs. It is supposed to lift 400-plus if you use mathematics. If you lift a 300-pound rock from the bottom, you have a couple of problems. How to keep it from getting away from you as it heads downstream, and how to stop it once it gets where you want it to drop — and how to do this all very safely. First, tie a line to the drum and anchor it to shore. The line may act as your steering system and will pull the drum in an arc towards the shore. This may or may not be the place you want it. To drop the rock, you want the safest way possible, and in my experience, that is a stop cock valve on the closed end. When you have the rock where you want, just crack open the valve, and the trapped air will leak out, allowing the drum and the rock sink to the bottom. You are well out of the way by floating on the surface or at least above the drum. Never swim directly above a drum full of air, as it has enough power to hurt you if it gets loose.

13) When placing the cables around the boulder for lifting, use a length of wood to push cable ends under the rock. Do not risk being caught by placing your hands down there. You may have to dredge away a couple of channels under the rock to pass cable through. Follow the above rules when doing so. When lowering the rock into place, try to set it down so you can pullout the cable. You may have to set the rock down on a couple of cobbles, but keep in mind the support may be wobbly as you try to remove cable. Post a warning sign at your dumpsite to warn divers away from potential loose rocks at least for the first season. The spring floods will have a tendency to settle the rocks into more stable configurations. The air-filled drums are great as long as you have deep enough water, and are not fighting the current as you wrestle them into place. If you have any sort of current, you will have to winch boulders. Post your pile of winched rock too, as it can be unstable for the unwary. When working underwater around your rock dump, keep the potential for instability in mind. Do not stand on any rock that could slide or move or you could be right into the situation which you were trying to avoid.

The above rules are a few that I have used and I have not had a problem, yet. Close calls do not count! There are others that could apply to specialized dredging situations, and it would be a real benefit to hear other people’s ideas for good safety practice. If we had enough input, a small manual could be compiled which would benefit all of us dredgers.

For those of you foolish enough to work around big rocks solo, the question is: “Why the heck didn’t I bring a buddy?”