With comments added by

Brian & Jim McCracken and Eric Bosch

“It was only Pure Luck that got us through this Whole Adventure.”

Note: This story was originally formatted as a pictorial-diary to document and memorialize one of the greatest adventures in my life. My brother Brian presented the pictorial presentation to me as a Christmas present in 1989. Many of the original pictures are included here.

Brain: I have known my brother, Dave Mack, for his entire lifetime. That’s because I was born two years ahead of him. During our growing-up years, Dave was “my younger brother.” Adventure has been Dave’s calling since his earliest days.

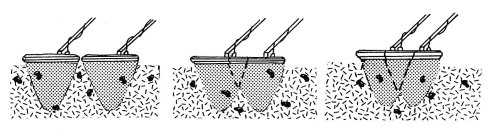

We grew up in a navy family. Our dad was a submarine commander during the cold war, so we were moving somewhere else every two years or so. When we lived near the water, Dave’s adventures nearly always revolved around boats. He devoted a winter to building his first row boat in the family’s living room when he was about 13 year’s old (we didn’t have a garage). The following summer, he used that boat to start a lobster-trapping business in Long Island Sound. Saving his money for something more substantial, Dave built his first motor boat in a friend’s garage the following winter – which vastly expended his reach out on the water. He got himself SCUBA qualified when he was 15, and most of his adventures after that revolved around being underwater. I remember he built this tow-sled to drag behind one of his motor boats, which allowed him to get dragged around with the ability to control his depth so he could search the bottom for signs of wreckage or anything else interesting. Dave and one of his friends used that sled day-in and day-out, searching for a sunken wreak that was supposed to be located near where we lived in Waterford, Connecticut. He never found the wreak; but until this day, I’ll bet nobody has covered more of the bottom of Long Island Sound off of Waterford, Connecticut. Dave was a heck of a good fisherman during those early years, and I never met anyone who could spear fish better underwater.

During the times we lived away from the water, Dave’s adventures were all about building forts. All the way back to the third grade, Dave was building them underground when we did not have access to trees. But Dave’s tree forts were the best. He built this fantastic, large 2-story tree fort back when he was in the 5th grade. A bunch of us pitched in to help with that project. We used that fort to make war with our next door neighbors of the time (the greatly-feared Garrett brothers). Those were several local guys of about the same age as us. We were kind of looked upon as “outsiders” because we moved around a lot. Dave came up with a big piece of tire inner tube and rigged a huge slingshot on top of our fort, and we were landing big green apples about a hundred yards over the trees to smack against the (much smaller) tree fort of our neighbors. We couldn’t even see their fort; but we could certainly hear when our apples struck home. In turn, they lobbed pretty sizable rocks in our direction. Those guys were not really our enemies. “Making war” from elevated forts in the trees was fun; something exciting for boys to do. Those skirmishes eventually evolved into battles with BB guns. We were lucky nobody ever got hurt really bad. We lost interest in war with our neighbors when the Garrets and several other local guys, Tommy Tracy and Peter Oats, started a rock band. That’s about the time that Dave really got going with his sea adventures – and I got interested in girls.

Dave’s tree forts were built so well, we used them as a place to meet up (mostly with our girlfriends) all the way until our youngest brother, Jim, graduated from high-school. Jim tore the fort down before he departed Connecticut to meet up with Dave out in California. It must have been a big job taking that fort down!

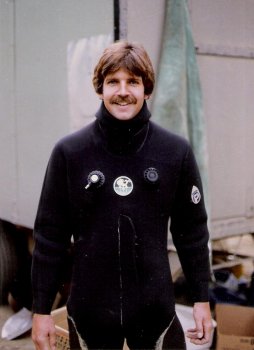

Being the oldest, I was strongly influenced by our father and was somewhat strong-armed into the U.S. navel academy at Annapolis just after high-school. Dave was much-less of a conformist. Rather than being pushed off on a university by our father, he and his best friend devoted most of their senior year in high school making a camper out of a Chevy step van (bread truck). They saved their money and departed on a year-long trip zigzagging across Canada and the U.S., eventually to end up out in California. After a time, Dave decided to join the navy and try out for the Navy Seals. The Seals were a seriously-dreaded program at that time (during the Viet Nam war), and I’m not sure any of us believed Dave would make it through the training. It was probably more of a surprise to our father than anyone that Dave actually did make it into the navy Seals!

After that, Dave and I were fortunate that our time in the service brought us together in Subic Bay, Philippines during 1975. That was another very interesting time. We shared some very hair-raising (and probably illegal) adventures there, as well. But we will save those stories for another day.

After that, Dave and I were fortunate that our time in the service brought us together in Subic Bay, Philippines during 1975. That was another very interesting time. We shared some very hair-raising (and probably illegal) adventures there, as well. But we will save those stories for another day.

This particular adventure started during the winter of 1981. Dave had already been dredging gold for about a year or two and was just starting to figure out how to find the high-grade gold deposits. I was between jobs at the time and invited myself to spend the winter of 1981-82 dredging with Dave on the Trinity River in northern California. There was snow on the ground, man; it was freezing! We lived in a timberline tent, heated by a wood stove. Dave lived out there in that tent for the better part of three years. It was something you adjusted to after a while. Dave and I took turns on the cooking detail. We ate a lot!

Now, anyone that knows Dave, knows that he is a hard-pusher. “No pain, no gain!” You had to get the work done if you wanted the gold to add up. End of story! We dredged as hard as we could nearly every day.

We were dredging right out in the middle of the Trinity River about 8 miles upstream from where we were camped. To minimize the pain involved of trying to get into a diving suit out in the snow and mud, we were getting into our dry-suits in the warm tent and then driving up to the claim. All we had to get around with at the time was Dave’s Honda motorcycle. I used to ride on back, balancing a fuel container on each side of the bike, hugging Dave with my legs to keep from falling off the back. There was often snow and ice on the road. We used to get some pretty strange looks from others who were driving cars. But it was just another day to us. No pain, no gain!

The water in the Trinity River that winter was ice cold, sometimes down in the mid-30’s. We were doing two long dives in that cold water every day. We would stay in until our bodies were so cold, we could not take it any longer. Sometimes, even before lunch, we would do jumping-jacks on the bank to get some heat fired back up in our diving suits. Our toes were so numb, they were beyond feeling. The second dive of the day was always the hardest. Many times, we stood there and dared each other to be last, “one, two, three, go!” and we would both be still standing there looking at each other, sometimes laughing at our situation. It was hard, but we did it. Placing your face in the water was like getting smacked in the head with a power slap; it stung something awful and gave you a splitting headache! I always dreaded that part of it.

Still, we were recovering quite a bit of gold for our effort, including some nice, big nuggets. It wasn’t enough to get rich. It was enough to get by. Uncovering cracks that were loaded with gold on the bottom of the river, sometimes even pockets of gold, was serious adventure! We were hoping for a real bonanza, but we just found steady gold.

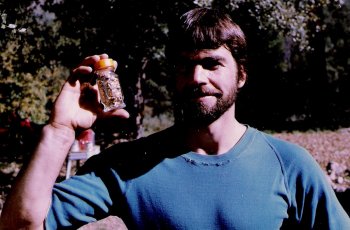

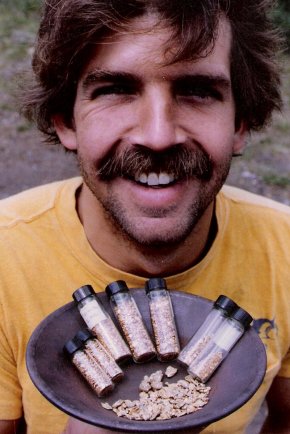

If Dave wasn’t filling up spice bottles with gold, he would just keep sampling around until he found a richer gold deposit!

If Dave wasn’t filling up spice bottles with gold, he would just keep sampling around until he found a richer gold deposit!

If the gold prices in 1982 were the same as they are today, we would have been making some serious money! But as it was, we were having to sell a lot of the gold we mined so we could pay for fuel, food and the other costs. We were keeping the nuggets, though!

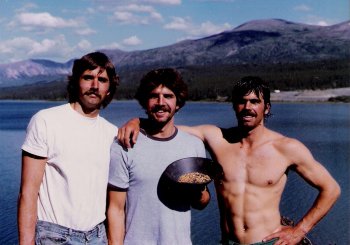

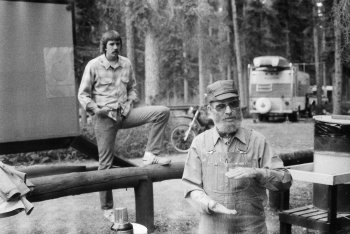

One day, Dave suggested that we should spend the upcoming summer season dredging in Alaska. I immediately jumped on the idea and ran it by our younger brother, Jim. Jim had never done any gold dredging, but he had been getting an earful about it from Dave and me. Jim immediately signed onto the plan. Dave then ran the idea by one of his best dredging buddies, Eric Bosch. Eric could not have been more than about 18 years old at the time. His mother, Anita, told Eric he could go with us on the condition that we also take along her young black lab, Sadie, to help protect us from grizzly bears. Eric & Sadie jumped right on board. That made five of us. One day I suggested to Dave that we bring a cook along so we could devote most of our efforts to mining. So Dave arranged with this strange old prospector named “Joe” to go along with us on the trip. Joe had a 3-inch dredge. In exchange for cooking and cleaning up after the rest of us, Joe was going to be allowed to mine for gold in his spare time. That made six of us.

Jim: This was a life-long dream come true for me; going to Alaska with my brothers on a gold mining adventure! Everyone else was just as excited about it as I was.

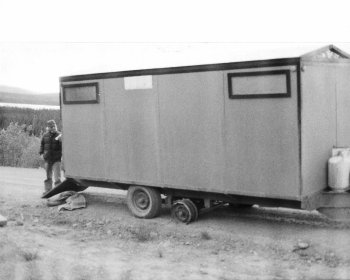

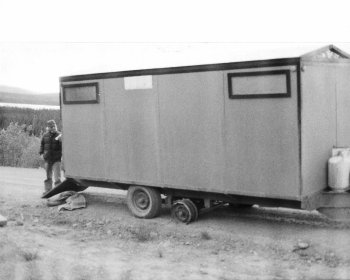

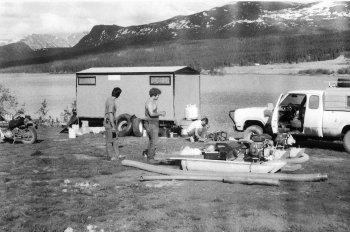

Brian: After taking some time to prepare, we all met in Big Bar, California in Mid-May of 1982. Big Bar is a small community nestled along the Trinity River. Dave had already acquired a beast of a Dodge Power Wagon that was in pretty sound shape. When Jim and I arrived in Big Bar, Dave and Eric had nearly finished building-up an 18-foot box trailer that we would pull behind the truck. The trailer would be used to haul Dave’s 6-incher, three 5-inchers and Joe’s 3-inch dredge, along with all the support gear and supplies that we needed. Then it was to serve as a cook shack and bunk house once the gear was removed. We located and installed propane and 12-volt lights, along with a very large, old propane freezer. We installed a wood stove with a removable smoke stack. This was a lot better than a tent!

Dave: Brian and Jim both grew full beards before they arrived so they could look the part of “Alaskan miners.” They looked pretty good, too. So they were real disappointed when I asked them to shave the beards off. I was warned in advance by some Canadian friends that we should not go up there looking all rough and burly, especially if we planned to do any business in Canada. I predicted in advance, if the opportunity presented itself, that we might want to stop in British Columbia or the Yukon Territory on the way to Alaska and do a little mining. Eric and I had already trimmed ourselves up even before Brian and Jim arrived. We were going to play it safe and project a clean-cut image.

Brian: There was still more work to do when Jim and I arrived on the Trinity. We all jumped to it, and we departed exactly on schedule at 10 AM on the first of June, 1982.

We had mounted an old camper shell and had removed the back window out of the truck so that the six of us could ride together. We had no plans to stop until we reached Alaska, except for fuel and meals – which we made for ourselves (mostly sandwiches) to save money. Eric’s small row boat was tied down to the top of the camper. We were really loaded!

Jim: The first part of the trip was really hairy. This was because the trailer was wandering around dangerously behind the truck – especially if we got going faster than about 45 miles per hour. As hardy as that Power Wagon was, our trailer was packed full to the top with heavy gear. All we started with was a bumper hitch. We could not load any more weight in the front of the trailer without fear of breaking the truck. There was so much weight on the bumper, sometimes it felt like we were pulling a wheelie down the highway!

In Portland, Oregon, we finally decided to stop and buy an anti-sway bar that connected between the truck’s bumper and the trailer hitch. That made all the difference, and we were able to pick up the pace. After that, we started making pretty good time, shifting off with the driving, taking turns sleeping in the back. We traveled day and night.

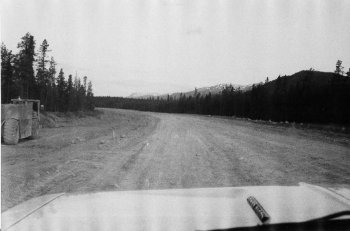

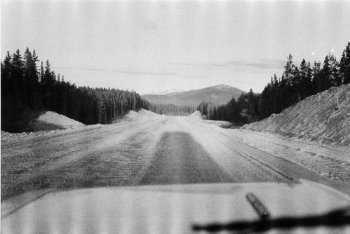

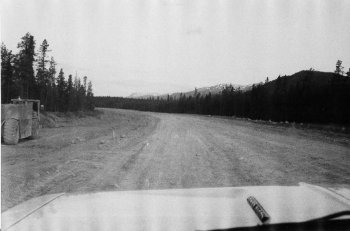

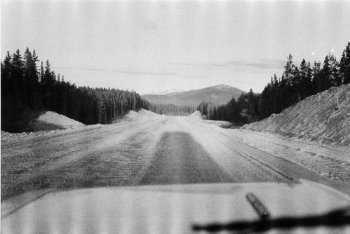

Eric: We started going through tires on the truck shortly after we got on the road. Before we reached Whitehorse, I believe we replaced every tire at least once. The trailer tires had plenty of tread on them when we started, but they were old and could not take the heavy load, especially once we reached the Alcan Highway in Canada, much which remained unpaved at the time.

Brian: We drove straight on through, day and night, hour after hour. But we had a reliable tape deck and brought along some great music. We were rocking out to Pat Benatar, Sticks, the Alman Brothers Band, Santana, Steve Miller and other rock n’ roll music that each of us had brought along. The rule was that whoever was driving got to pick the music. Our old companion, Joe, from an earlier generation, was having visible trouble adjusting to our music, but he was not really complaining, yet. That came later. For the moment, we were moving right along. We were on the Alcan Highway by the third day.

Never mind that we were in June; it was cold once we began driving through the Canadian Rockies. It was like 14 degrees during the daytime and got really cold at night.

Jim: One morning at around 6 AM, just as it was getting light, I was driving along (dirt road) at about 50 miles an hour; and just like that, it was everything I could do to keep the steering wheel in my hands. Everything was flipping out of control!

Brian: I looked out the window and saw the trailer right next to us! I remember thinking, “What’s going on?” It turned out that we got a flat back on the trailer, and then broke one of the bolts that held the leaf spring to the trailer’s frame, causing the trailer to fishtail all over the place. We were quite fortunate that we did not completely jackknife and roll both the truck and trailer right there. That would have been the end of our trip, big time! We were lucky!

We really did a number on that wheel, but we were feeling lucky that we had not lost the whole trailer!

Eric: It was our first flat on the trailer. We also destroyed the wheel rim. This was not just any rim; it was something special from an old trailer axle. Fortunately, we had brought two spares. Unfortunately, to place more weight in the front of the trailer, we had stored both spares all the way in the front of the trailer. That was a mistake we only made once! So there we were on the side of the Alcan where we needed to unpack nearly the entire trailer just to get at our spares. We all felt pretty foolish about that. This is one of the things you learn on a trip to Alaska: Plan on getting flats!

While Dave and Jim worked on unpacking and repacking the trailer, Brian and I drove the Honda motorcycle 20-miles back to the nearest town to find a hardened steel bolt that would reattach our leaf spring. This was a bit of a challenge, since Canada is on a metric system, and the bolt went along with a bushing that had to fit just right. It took us a while, but we finally found what we were looking for. The store had three in stock. We bought all of them!

When we returned to the trailer, we were about frozen to death! The temperature was below freezing. Brian and I had to take turns driving the Honda, because it was so cold on the guy in front. When we got back to the trailer, Dave and Jim were waiting for us with the spare tire ready to go. In all, we only lost about half a day.

When we returned to the trailer, we were about frozen to death! The temperature was below freezing. Brian and I had to take turns driving the Honda, because it was so cold on the guy in front. When we got back to the trailer, Dave and Jim were waiting for us with the spare tire ready to go. In all, we only lost about half a day.

Dave: The bigger problem was that we were going through our money much faster than we had planned. Pulling that heavy load, the Power Wagon was only getting about 4 miles to the gallon of gasoline; 6 at the most, even when we were going down hill. We had to buy things along the way that we had not planned for, especially tires. After we blew the second tire on the trailer, we went into a tire store and bought 4 brand new ones. It was too risky to run the Alcan with such a heavy load on those old tires!

Out of pure luck, we also were able to find another spare rim for the trailer. This turned out to be very fortunate, because we lost another rim one day when I was driving. We had just topped another hill, and I was manually applying trailer breaks as we descended the other side. We were totally overloaded, and the last thing we needed was to get going too fast down a hill on a dirt road!

I’ll never forget driving down this hill and getting passed up by a wheel that went right by the driver’s side. It was going quite a bit faster than we were. Maybe it was sleep depravation, but I could not put any logic to it. My first thought was that it was someone else’s wheel. But we were the only ones out there! About the time the wheel bounded off the road and out of sight down a steep hill, it occurred to me that it might have been one of our own wheels. Sure enough, when I looked in the  rearview mirror, I could see that the break drum from the rear left wheel on the trailer was down rolling on the road. Great! Luckily there was no serious damage. But it took us hours down in the brush before we finally found the wheel. The lug bolts had torn right through the rim, rendering it useless. But the tire was still good.

rearview mirror, I could see that the break drum from the rear left wheel on the trailer was down rolling on the road. Great! Luckily there was no serious damage. But it took us hours down in the brush before we finally found the wheel. The lug bolts had torn right through the rim, rendering it useless. But the tire was still good.

Eric: One night, we came up over a hilltop and the entire sky was lit up in a blaze of bright-colored white, yellow and red electricity. It was so dramatic and sudden that we pulled the truck over to the side of the road and had this very serious discussion, trying to decide what was going on. We finally came to the conclusion that there must have been a nuclear war. We turned on the radio for news, but there  was no reception out there. There were also no other vehicles on the road. We even had some discussion about turning around and going back home. That’s when Joe, who was dozing in the back of the truck, sat up and said, “No, you knuckleheads, those are the Northern Lights!” The entire sky was on fire with an electric light show. We grew quite accustomed to this later in the trip after the midnight sun would disappear, again.

was no reception out there. There were also no other vehicles on the road. We even had some discussion about turning around and going back home. That’s when Joe, who was dozing in the back of the truck, sat up and said, “No, you knuckleheads, those are the Northern Lights!” The entire sky was on fire with an electric light show. We grew quite accustomed to this later in the trip after the midnight sun would disappear, again.

Brian: It took us a full five, long non-stop days to reach the town of Whitehorse in the Yukon Territory. We were down to our last 200 Dollars. That wasn’t even enough to get us up into Alaska! Basically, we were broke! We found a camping area just outside of town, set up some tents, and took a timeout to get some real sleep, clean things up a bit, and take stock in our situation. Our financial situation was not good. We were going to have to come up with some money!

Even though we were out of money, Joe was always asking us to buy something else that he needed to do the cooking properly for us.

Jim: We were just young guys in those days, and we had already invested all of our savings into this trip. There was no more! By the nature of the way we were raised by our father, looking back on it, I don’t think any of us even considered the idea of asking him for a loan. Not that he wouldn’t have helped us. Sure he would have. But the price to pay for telling our dad that we had gotten ourselves stuck up in the middle of nowhere with no money would have been way too much to pay. We would have looked for dishwashing jobs before we did that!

Dave: I knew an American gold buyer who was based out of Whitehorse during the summer months. It was something about the Dollar exchange between the Canadian and U.S. currencies that was making it work for him and the Canadian miners that he was buying gold from. He told me to look him up when we reached Whitehorse. I had his phone number. So I gave him a call as soon as we had a chance to catch our breath. He invited me over to his office. Jim and I drove the motorcycle over there from where we were camped.

Jim: The first thing we learned in Whitehorse was that Canada was strictly enforcing a motorcycle helmet law. We barely got into town, and were sternly scolded by an RCMP officer (Royal Canadian Mounted Police) from the open window of his cruiser on the far side of the street. He yelled at us so loudly that I thought we had joined the Marines. He was a totally no-nonsense dude. He said, “Get some helmets on or else!” We said, “Yes sir!”

Dave: After advising my friend of our situation, he suggested that he could introduce us to some of his clients that were recovering hundreds of pounds of gold from ancient gold deposits located adjacent to Pine Creek near Atlin, British Columbia. This location was more than a hundred miles from Whitehorse (that is a 3-hour drive on today’s roads according to Google Earth). My friend was pretty certain these Canadian miners would allow us on their creek since they were not doing anything with it. And if not there, my friend said we would turn up others near Atlin that would allow us to dredge on their property.

Atlin has a fantastic gold mining history; it is one of the richest areas in all of Canada. The standard dealwas 10% of gold recovery to the claim holders, and another 5% finder’s fee for my friend. That seemed more than reasonable to me and my partners!

Within just a few days, we had made 10% deals with several claim owners in the Atlin area. Let me just say that while America might be the super power, generally speaking, we do not even come close to matching up with what the Canadians are doing with mining. The miners who we were being introduced to were operating whole fleets of huge earth-moving machines. They were literally removing hundreds of feet of overburden to gain access to extremely rich layers of pay-dirt. When they saw our tiny 5-inch Keene dredges, it was only politeness that kept them from laughing out loud at us! I’m sure we made for amusing discussion at the local bar, because we heard about it later. To them, we were just playing. Besides, they had zero interest in Pine Creek, because their forefathers had already mined the creek…

Within just a few days, we had made 10% deals with several claim owners in the Atlin area. Let me just say that while America might be the super power, generally speaking, we do not even come close to matching up with what the Canadians are doing with mining. The miners who we were being introduced to were operating whole fleets of huge earth-moving machines. They were literally removing hundreds of feet of overburden to gain access to extremely rich layers of pay-dirt. When they saw our tiny 5-inch Keene dredges, it was only politeness that kept them from laughing out loud at us! I’m sure we made for amusing discussion at the local bar, because we heard about it later. To them, we were just playing. Besides, they had zero interest in Pine Creek, because their forefathers had already mined the creek…

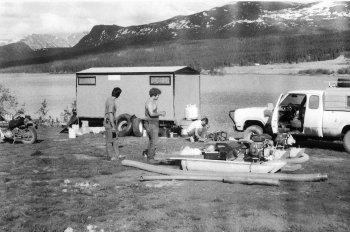

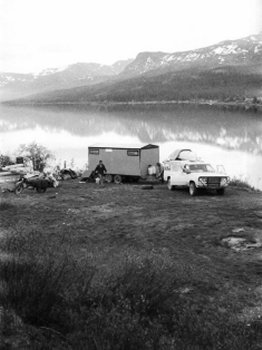

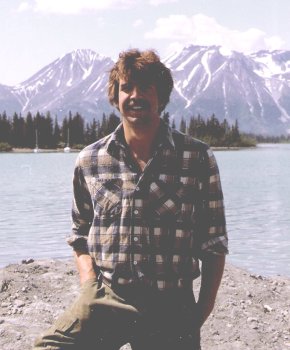

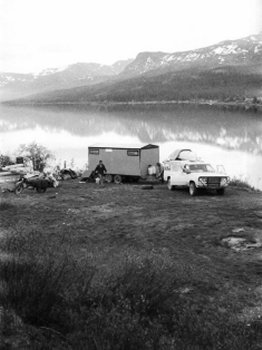

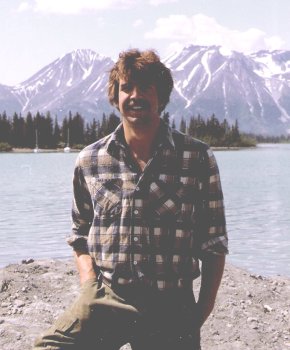

Brian: We found this wonderful place to camp up on Surprise Lake, which was about 15 miles upstream from Atlin on Pine Creek. It was an organized campground with a pit toilet, but we were the only ones there. The surroundings were outstanding! We didn’t know it until we pulled in there, but this turned out to be a renowned fishing area with glacier-fed lakes (cold), beautiful rivers and creeks, surrounded by snow-capped mountains. It was now mid-June, and there was still 3-to-4 feet of snow on the ground in some places. Surprise Lake overflowed to begin the lower stretch of Pine Creek.

Unfortunately, the entrance into the campground was very rough and we broke a leaf spring on the trailer getting into the campground, something we would have to replace before we could leave.

Unfortunately, the entrance into the campground was very rough and we broke a leaf spring on the trailer getting into the campground, something we would have to replace before we could leave.

Eric: After unloading all the mining gear and setting up camp, I decided to row out on the lake and see if I could catch any fish. Mainly, I was just happy to get out of that truck. The guys kind of laughed at me when I first went out there. This was because they were used to fishing on lakes in America where you usually have to work hard to catch even a small fish. I had a nice big fish in the boat after my first cast! That sent the other guys running for their own fishing gear. Then, everybody got into the act and we were catching fish like crazy! Later, Jim and I rowed over to the other side where a small creek was emptying into the lake, and these same fish were trying to get up the very shallow creek in such large numbers that we could have gathered up as many as we wanted.

We were the only ones out there camped on this beautiful lake that was full of fish!

Dave: One thing we noticed as soon as we got into Canada was that things seemed a lot more expensive there than what we were used to. This was even more true when we got out to Atlin. Just a medium-sized jar of peanut butter was like $10. And we were some hungry boys. Since our money needed to be spent on fuel for the dredges, we felt we needed to do something drastic to get some meat in the freezer.

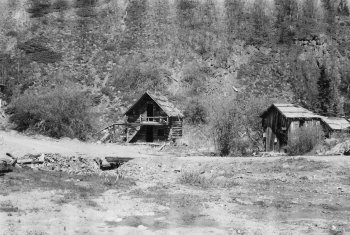

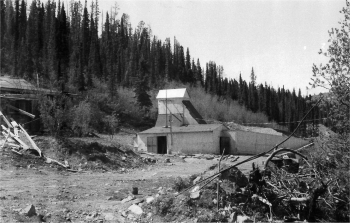

Jim: The day after setting up camp at Surprise Lake, Eric and I went hunting on the Honda. There were all sorts of primitive roads out there, and we had to be careful to not get lost! As we started driving around, it became clear almost immediately that we were in the middle of a massive, historical gold mining area. There were old miner’s shacks and old mines around nearly every bend! Gold prices were very low at the time, so most of the buildings and mines were abandoned. There was hardly anyone around, except for an occasional person or two we would see driving around from time-to-time. It seemed pretty safe to go on an unlicensed hunting trip.

Eric: We had brought two weapons with us on this trip. The first was a shot gun that we literally had loaded and ready for potential bear attacks. The second was my trusty Winchester 30-30. This was my personal favorite hunting rifle. I had knocked off a lot of dear using this gun. Since I was familiar with the 30-30, Jim agreed that he would drive the motorcycle and let me take a shot if we spotted any game.

Similar to the way we underestimated the fishing, we realized how plentiful the game was before we had traveled more than about a mile away from camp. Jim followed the road around this bend; and there was an entire herd of these huge animals right out in an open meadow. We didn’t even know what they were. It was meat! They were so close; I didn’t even have to get off the back of the motorcycle to nail one. He went down in a single shot!

Jim: Dave and Brian had gone off in the truck to case out where we would begin our dredge sampling program on the following day. So Eric and I went back to camp and got one of the tarps that we had brought along, some knives and some trash bags. Then we spent the rest of the entire day cleaning that big animal and packing hunks of meat to our freezer in camp. We stocked it completely full of meat. We then dragged the remaining carcass off out of sight to help feed the wolves (which were surely there). When Dave and Brian returned later that afternoon, Joe already had steaks cooking on the Barbie! Things were looking better. Worst case, we could just eat fish and meat until we started mining some gold. We were not going to go hungry out there! But our money shortage forced us to place a severe limit on what we would spend on food in the store.

Jim: Dave and Brian had gone off in the truck to case out where we would begin our dredge sampling program on the following day. So Eric and I went back to camp and got one of the tarps that we had brought along, some knives and some trash bags. Then we spent the rest of the entire day cleaning that big animal and packing hunks of meat to our freezer in camp. We stocked it completely full of meat. We then dragged the remaining carcass off out of sight to help feed the wolves (which were surely there). When Dave and Brian returned later that afternoon, Joe already had steaks cooking on the Barbie! Things were looking better. Worst case, we could just eat fish and meat until we started mining some gold. We were not going to go hungry out there! But our money shortage forced us to place a severe limit on what we would spend on food in the store.

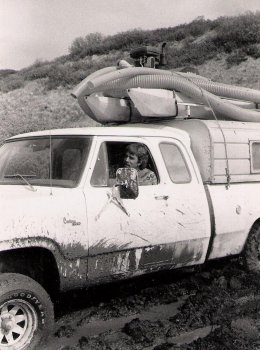

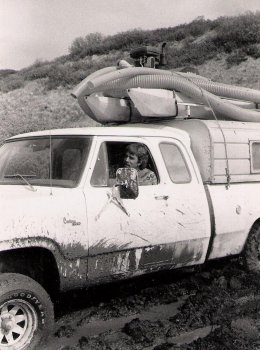

Brian: Before deciding where to begin sampling, we spent quite a bit of time driving around the surrounding area. As they were in their spring thaw, the side roads off the beaten track were mostly wet and muddy. We got stuck several times even with the 4-wheel drive. Ultimately, we decided the best way to deal with the muddy sections of road were to hit them hard and fast so the momentum would carry us through. Boy, that old Power Wagon was like an army tank!

Brian: Before deciding where to begin sampling, we spent quite a bit of time driving around the surrounding area. As they were in their spring thaw, the side roads off the beaten track were mostly wet and muddy. We got stuck several times even with the 4-wheel drive. Ultimately, we decided the best way to deal with the muddy sections of road were to hit them hard and fast so the momentum would carry us through. Boy, that old Power Wagon was like an army tank!

Here was Brian charging through a bog at about 60 miles an hour!

Dave: The local claim owners that we were working with owned several miles of Pine Creek. But there were only a few places which allowed direct road access. So, on the following day, we launched a 5-inch dredge and decided to knock out a sample hole right there where the road met the creek. There was still snow and ice on the edges of the water. The creek was ice-cold! We all had dry-suits to keep our core temperatures intact. But I got a migraine headache that hurt so bad that it turned my stomach every time I stuck my face in that water; no exceptions!

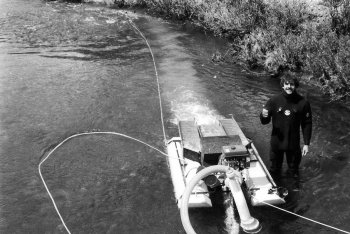

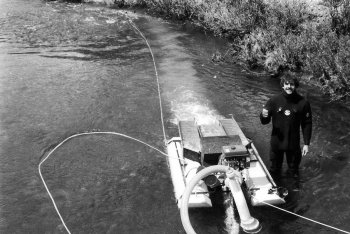

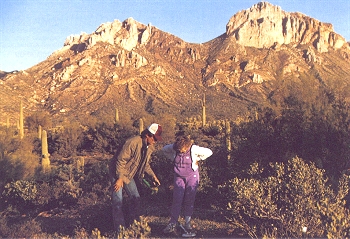

Jim giving the thumbs-up signaling that we were recovering gold on the first sample.

Amazingly, we got right into pretty rich gold on the first sample hole! The gold was sitting right on top of a layer of hydraulic tailings, under about two feet of hard-packed streambed material. This was gold that was lost from old-timer recovery systems. There were a lot of fines and flakes. There were also some nice gold nuggets! We were making money on the first day. Things were looking up!

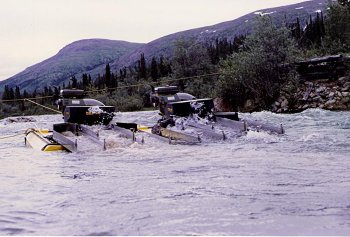

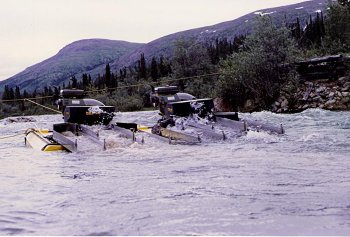

Production dredging in the first gold deposit we found on Pine Creek.

We launched my 6-incher on the following day and decided to shift-dive the dredges, one person down on each of the two dredges at a time, while the other two guys had a chance to warm up. We wanted to do some production dredging in the deposit to see how the gold was going to add up before we committed the other two dredges.

It was going pretty good. But, things were so expensive up there, it didn’t take long to realize that we needed to find a richer gold deposit if we wanted to come out ahead after all the costs. When I say “come out ahead,” I mean we wanted to come out way ahead!

Here is the sun at about 3 O’clock in the morning!

Eric: By this time, it was not really getting dark at night. The sun got smaller, kind of like the moon; but it never really got dark. This had the four of us out on the creek until very late in the day. Working in the cold water gave us insatiable appetites! This all came to a head one evening when we returned to camp and Joe had not cooked nearly enough food to feed our hungry appetites. He was also complaining bitterly that he had no way to get to the creek after we went off for the day — so he was not able to get any mining in. Joe generally had a negative emotional attitude. He was just made up that way. His negative emotions were something that had been dragging on all of us for the whole trip. It all came to a head that evening with the rest of us fiercely growling (in hunger) at Joe that he must feed us more! We were so angry at him; I believe Joe thought we were going to kill him. This is not an exaggeration. From then on, Joe was fearing for his life!

Eric: By this time, it was not really getting dark at night. The sun got smaller, kind of like the moon; but it never really got dark. This had the four of us out on the creek until very late in the day. Working in the cold water gave us insatiable appetites! This all came to a head one evening when we returned to camp and Joe had not cooked nearly enough food to feed our hungry appetites. He was also complaining bitterly that he had no way to get to the creek after we went off for the day — so he was not able to get any mining in. Joe generally had a negative emotional attitude. He was just made up that way. His negative emotions were something that had been dragging on all of us for the whole trip. It all came to a head that evening with the rest of us fiercely growling (in hunger) at Joe that he must feed us more! We were so angry at him; I believe Joe thought we were going to kill him. This is not an exaggeration. From then on, Joe was fearing for his life!

The meals were much bigger after that, and Joe was sending each of us out with three thick peanut butter plus two cheese sandwiches per day. We were using most of the gold we were mining to buy more food at the local store. We were eating it all.

Joe never got in a single moment of mining. All his time was devoted to meal preparation and clean-up. He was quiet and sullen. He was very hard to read, but we could all sense his resentment. We were not sure if he was worried that we were going to kill him, or if he was perhaps planning to poison us. We were all regretting that we had brought him along.

We had to back out of our dry-suits one person at a time to keep from being swarmed by millions of hungry mosquitoes!

We had to back out of our dry-suits one person at a time to keep from being swarmed by millions of hungry mosquitoes!

Jim: The mosquitoes along pine creek were so ferocious; that to keep from being eaten alive, we each had to get out of our dry-suits one person at a time, with the other three guys waving the mosquitoes off. The (big) mosquitoes would literally swarm us in clouds!

Brian: After we got a few ounces of gold ahead, we made a special trip in to Whitehorse and sold it to Dave’s friend (he paid us $260/ounce at 70% of the spot price), and we used the money to stock up on fuel, food and supplies. We were filling two 55-gallon drums with fuel in the back of the truck. Fuel and supplies cost us much less in Whitehorse, than in Atlin.

Dave: One of the T-80 air-breathing compressors from the two new 5-inch dredges we had bought from Keene Industries lost a bearing on the first day. I called Jerry Keene and asked if he would please send us a replacement. He said no problem. So I gave him a General Delivery address for Atlin, British Columbia. One of our 5-inchers was going to be out of action until the compressor arrived.

After a few days of working this first gold deposit, we decided it would be best if Jim and Brian continued to work it to produce income, while Eric and I, who were the most experienced, started a serious dredge-sampling program on Pine Creek. We needed to locate a richer gold deposit!

The claim owners were coming down every few days to see how we were doing. They were impressed with what we were recovering, surprised that we were finding any gold at all from the creek. They were also showing us some of the larger nuggets they were finding. The claim owners were into really big gold, and lots of it!

Eric: Since the creek was accessible by road up there, Dave and I just started up by Surprise Lake, dredging sample holes as we drifted downstream towards where Brian and Jim were dredging. The water was freezing, so we shifted off, each taking turns. We didn’t find very much gold during the first few days, so we were starting to get a bit discouraged. Still, Dave and I had learned from previous experience that the only way to win was to continue the best we could with enthusiasm.

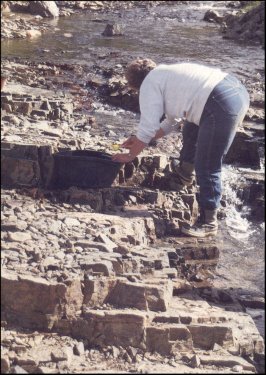

Dave: Eric and I had just successfully maneuvered the dredge down through a very bad set of rapids. This required him to run downstream with the dredge to get it lined up just right. I was downstream with a rope and had to pull the dredge across the creek just at the right time, to keep it from smashing into some boulders out in the current that certainly would have flipped the dredge over (which would have been a disaster). The operation went smooth and we were pleased with ourselves. We set up to do a sample hole just below the rapids. It was my turn.

Dave: Eric and I had just successfully maneuvered the dredge down through a very bad set of rapids. This required him to run downstream with the dredge to get it lined up just right. I was downstream with a rope and had to pull the dredge across the creek just at the right time, to keep it from smashing into some boulders out in the current that certainly would have flipped the dredge over (which would have been a disaster). The operation went smooth and we were pleased with ourselves. We set up to do a sample hole just below the rapids. It was my turn.

After getting through my blinding headache, I dredged a sample hole right out in the middle of the fast water. The streambed was only about a foot to bedrock, so the sample was completed pretty fast. I only saw a smidgen of gold on the bedrock; it was not what we were looking for!

As I was dragging the suction hose back into the slower-moving water towards the side of the creek, it occurred to me that I ought to try a sample there. That was a moment of fate. To this day, I remember the thought process playing out: “Should I or shouldn’t I?” You have to have your mind and emotions in the right place to find high-grade gold. It is a lot about getting dialed into the right wavelength. Since the streambed was so shallow to bedrock, I decided to dredge another hole. That single decision changed the outcome of this whole adventure, and that of the others who were with me! A whole philosophy could be built up out of this single idea that virtually every decision we make in our lives affects the final outcome for each of us, and perhaps, to some degree, for all of us!

In closer to the bank of the creek, only about 6-inches into the streambed, I could see that I was getting into something entirely different than what we had seen in any of our earlier experiences along Pine Creek. This was a much harder, older material. I immediately saw the gold spread all throughout the material. Unbelievable; we struck it rich!

I took a moment to uncover an entire pothole along the bedrock that was completely filled with gold nuggets!

Eric: Dave came up and told me to bring my mask over and take a look. As painful as the cold water was, I already knew he must have turned up something really good. Heck, he was only in three or four feet of water! When I stuck my head in the water, I could see the gold even before I dipped down closer to take a look. The small area he had uncovered with the dredge had gold spread all over it. It was the richest gold deposit I had ever seen!

Dave: After Eric got a look, I took an hour or so and tried to load the sluice box with gold. I wanted it to be the most abundant clean-up I ever had. The streambed material was just pocked full, all throughout with gold. The cracks and holes in the bedrock were completely full of gold. It was, by far, the richest deposit I had ever seen. One thing I noticed was that the streambed material was so hard that it was coming apart in clumps. I didn’t give much thought to this, mainly focused on getting as much material sucked up into the dredge as I could.

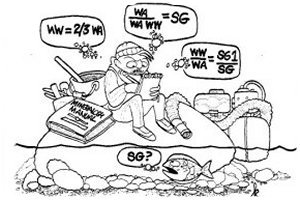

When I ended the dive, I was disappointed that there was not more gold in the dredge’s sluice box. The riffles should have been overflowing! Don’t get me wrong; there was a lot of gold there. But there should have been more! Then it occurred to me that I should look at the dredge’s tailings…

Eric: The box was loaded with gold when Dave came up. It was, by far, the best clean-up I had ever seen. There were beautiful nuggets up to ¼-ounce in size. The riffles were loaded with flakes. I just could not believe our good fortune. It was soooo amazing how things had changed for us in just a single sample hole!

Then Dave put his mask on and looked at the tailing pile. He came up and told me to take a look. I don’t recall that either of us were experiencing cold-water headaches at that time. I could see that the tailings pile was almost entirely made up of streambed clumps of hard-pack that remained full of gold. The clumps had washed right through the sluice box carrying the gold along. It looked as though there was more gold in the tailings, than we had recovered in the sluice!

Dave and I devoted the remaining part of the day scooping all those tailing into our clean-up tub. We then broke up the material as best we could to release the gold. After our clean-up, we floated down river to where Brian and Jim were just finishing up their day. It was late; maybe 8 or 9 PM. But, by the light in the sky, it might just as well been five O’clock in the afternoon.

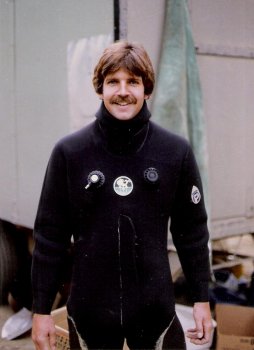

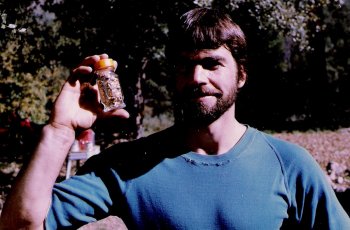

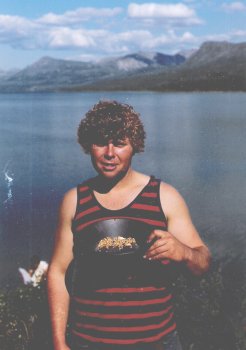

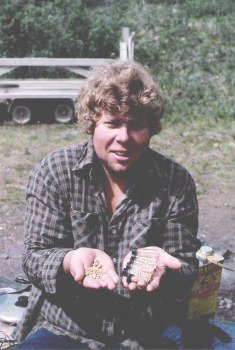

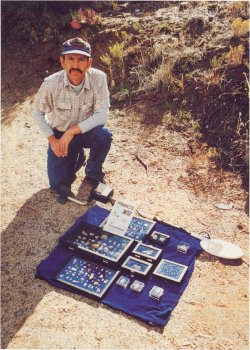

Eric showing off our first serious clean-up. It was around 8 ounces for about an hour of dredging.

We were all in a celebration mood that night! We probably worked till 2 AM doing final clean-up on all that gold, rocking-out with Pat Benatar, Led Zeppelin, Steve Martin and some Rolling Stones. Joe saw our gold and immediately retreated to his tent. I suppose I was closest to him of anyone on the trip. He had completely separated himself from all of us, including me. The only feelings coming from Joe were resentment. It was starting to feel very wrong for us to have someone with that much resentment preparing our food for us…

Dave: We had to come up with a new plan on how to work this very compacted streambed material so we could avoid washing clumps of gold right across our recovery systems. These days, we would just hook up a pressure washer to break up the gravel. But this all happened long before low-cost pressure washers were on the market.

Finally, we decided that we would sacrifice the following day making a trip into Whitehorse and buy some geology rock picks at the local prospecting store. We would sell some gold and stock up on supplies. I had also received a notice from Canadian Customs to stop by and pick up the T-80 compressor which had been shipped by Keene.

Jim: Not having any better ideas, and being worried about Joe, Dave, Brian, Eric and I began taking turns sneaking out into the forest and burying our rapidly-growing stash of golden treasure. Over top of what we were selling for expenses, our stash started adding up big-time as soon as we got into the rich deposit.

Brian: Our plan was to place all four dredges into this extremely rich gold deposit. We were going to float the two dredges from downriver upstream about half-mile to get them there. We were going to lower the other 5-incher down over the hillside with a rope as soon as we got the replacement compressor installed. It was looking like we could turn this into serious gold production. We figured we still had two months remaining in our season. We were gearing up!

Dave: Our first stop in Whitehorse was at Canadian Customs. They had sent a pick-up slip to me in care of General Delivery in Atlin. I went to the counter totally unprepared for what happened. After giving the slip to the lady, she brought the box over and set it down on the counter. I could see that the box had been opened. Without any fanfare, she looked me right in the eye and asked me what it was. I told her that it was an air compressor for a portable gold dredge. She then freaked out and demanded to know what I, as a U.S. citizen, was doing with a gold dredge in Canada? That’s when I realized this was not going as planned.

Improvising as best I could, I told her we were actually on our way to Alaska and stopped to do some fishing on Surprise Lake. I told her that we broke the compressor when we unloaded our trailer so we could have a living space on the lake. She wanted to know if we were gold mining in Canada, and I told her no (this gal knew a liar when she saw one). Then, she explained that I had no need for the compressor; and that I could pick it up when we passed through on our way to Alaska. Her boss was listening in. He seemed like a nice guy, older and more calm. He told her to give me the compressor. I took it and made a hasty retreat.

I have not been back up to Canada since then, so I don’t know the way things are these days. But back in 1982, the Canadian Customs authorities and RCMP officers were some no-nonsense, very serious officials! We had also got (forcefully) yelled at by the local RCMP officer near Atlin for driving the motorcycle around on the back dirt roads without wearing helmets. There was no politeness in the demeanor.

Jim: On the other hand, during our short time there, we had made friends with some of the local people – who were as hospitable as anyone we had ever met. We were buying some supplies in Atlin, going to the post office, using the pay phone in town to call home, and doing other business there. In our running around, we had gotten a chance to meet several other Canadians that were actively mining. They had extended open invitations for us to operate our dredges on their claims.

It turns out the Forth of July is also a big holiday in Canada, and the local mayor actually sent someone up to our camp one day to insist we go down and play in the annual fast-pitch softball game. We spent the entire Forth of July making friends with the very hospitable locals in Atlin. Everyone was really nice to us!

Dave: My encounter with the lady in Customs changed everything. It was clear from our conversation that our days dredging in British Columbia were going to be limited. Until I walked into Customs that morning, we had no idea that we were not allowed to mine up there. My understanding was that America and Canada have a mutual agreement which allows citizens from both countries to mine in either country. And while this is most-certainly true in America for Canadians (or anyone else who wants to operate a gold dredge in America), Canada turns out to have some very substantial bureaucratic steps that an American must take (before you even enter into Canada) prior to doing any type of commercial mining up there. At least that’s the way it was in 1982.

Eric: We went from Customs directly over to the prospecting shop and bought some geology rock picks, the kind with hard-pointed tips. We were going to use those to pick apart the gold-laden hard-pack on the bottom of Pine creek before dredging it up. The idea was to break the gold loose from the other material so it would get caught in our recovery systems. We also pitched out enough dough for two motorcycle helmets. Then we loaded up on groceries and fuel and returned to camp.

Jim: Our feelings of exhilaration from the day before now had a dark shadow hanging over us. We did not want to be in trouble. But we also did not want to walk away from all that gold!

Dave: Have you ever experienced the feeling of “impending trouble,” even when you don’t know exactly where it is going to come from? It’s like you know that powerful forces are organizing against you. It is the feeling of “being in trouble,” even though it has not caught up to you, yet. I saw the determination in the lady from Customs. This was not over. It was just starting!

Still, since we had made our discovery in a place along Pine Creek that could not be seen from the road (even though we could see from down on the creek when vehicles passed by up on the road), we believed that we could get some days of dredge-production on the creek before anything was going to happen. Actually, we were not even certain that anything was going to happen. The gold deposit was  so rich; it was only going to take a few days of production to put us in really good shape!

so rich; it was only going to take a few days of production to put us in really good shape!

We lowered the other 5-inch dredge down a steep hill on a rope to get it set up in the rich deposit as fast as we could.

Brian: With uncertainty hanging over us, we decided to drop the other 5-incher down over the side of the hill (with the new T-80 compressor back on board) and leave the two other dredges down near the creek access road for a while. This would allow us to get more time immediately dredging in the rich gold deposit. It was a good plan. After getting the second dredge down there and set up, we did shift-diving well into the first night, using two dredges side-by-side.

It had to be about midnight by the time we got back to camp. Joe was about to have a nervous breakdown when we pulled in. He was like an old mother hen, giving us a hard time about getting home so late while dinner had been ready for three hours. Actually, it occurred to us later that he might have been frightened to be in camp at night alone. This was grizzly country!

When we showed Joe the concentrate from the day’s production, he shut right the heck up and returned to his tent. The concentrate was loaded down with pounds of beautiful golden flakes and nuggets. It was just an unbelievable sight to behold!

We reheated our own dinner and ate quickly. Final clean-up took several more hours to complete. Now we were filling up bottles with gold. Some of the nuggets were too large to fit in the standard-sized 4-ounce bottles that we had brought along, so we emptied out spice bottles of their contents and started filling those up, too! I remember it was Eric’s turn that night to sneak off into the forest and find a hiding spot for the gold.

We hid the gold in a different place every night, carefully refilling and covering past hiding places so nobody would catch onto what we were doing.

Dave: One of Joe’s responsibilities was to be first up in the morning and get the coffee going. Since this was done inside the trailer, and I was bunked in the trailer, I was always up as soon as I smelled the coffee. Joe always poured me the first cup, because he knew I was going to want it as soon as I rolled out of my sleeping bag.

The following morning, I heard Joe come into the trailer, but did not hear him preparing the coffee. Everything was quiet, but I knew he was there. So, after a while, I rolled over and peaked out of my warm sleeping bag at him. Joe was just standing there, holding his crotch with both hands. Both of his eyes were rolled back in his head. He had flipped out on us! Concerned, I asked Joe how he was doing. Without even looking at me, he said, “I gotta get out of here!” He clearly meant it. So I told him I would arrange to get him on a bus towards home that very morning. He went off to pack his things. I made the coffee.

After getting breakfast and lunch together, we all drove into Atlin and dropped Joe off at the Greyhound station. A bus went through there every day. We bought his ticket home, gave him a few hundred Dollars for food, and slipped him two ounces of the beautiful gold that we had recovered just the day before. He was so surprised when we gave him the gold, we could see that he was having second thoughts about leaving. But we had already bought his ticket, and it really was time for him to go. So we each said our goodbyes to Joe and could see that he was crying as we pulled away in the truck. That was the last any of us ever saw of him. Some years later, Eric said he heard that Joe died of a stroke sometime shortly after returning to America.

After that, we started bringing the motorcycle with us to the claim. Each day, when we were winding down with the mining program, one of us would return to camp and cook dinner and pre-make lunch for the following day. We took turns. As much as we all got used to Joe, things were a lot lighter around camp after he was gone. We turned the music up louder!

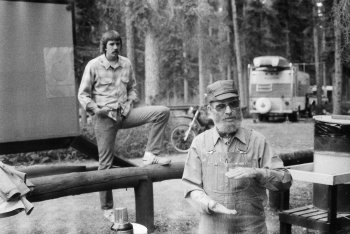

Dave & Jim with the all-important hot coffee.

Jim: Yeah; I remember one day it was my day to cook and I decided to take a short cut with Dave’s motorcycle back to camp. Dave and I were always into motocross riding when we were growing up. As I came down this hill, I drove through what looked to be a puddle and buried the Honda in muck all the way to the handlebars! As hard as I tried, I could not get the bike out of the water alone, so had I to hike back and get the guys to help me pull it out of the stink-hole. Dave was (rightfully) pissed off about that, because he loved that bike. He spent the next day in camp flushing all the water out of the engine and getting the bike operational, again. I’ll never forget the first time he pushed down on the kick starter and a whole bunch of dirty water gushed out of the exhaust pipe. I looked around, and Brian and Eric were doing everything they could to keep from laughing. We didn’t really lose much production out of it. The rest of us just worked all the harder to keep the dredges running while Dave fixed the bike.

There were no more short cuts with the Honda allowed after that!

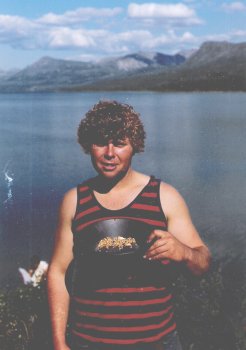

Eric showing off the clean-up from our second day; more than double

what we did with a single dredge, but only in a few hours of work.

Eric: Our second production day with the two 5-inch dredges was much better than the first, even though we lost quite a bit of the day getting a second dredge into action and moving everyone’s dive gear to the new location. The deposit consisted of around two feet of black-colored very hard-packed material. It was laced full of gold! This special material would disappear once we got out into the creek a ways. But the rich material extended right up under the bank. It was on the second day that we recognized that we were dredging directly under an old water ditch that had once followed alongside the creek. Remnants of the old ditch could still be seen for a long way. Best we could tell, the old-timers never mined under the ditch. This was a near certainty, because if they had, the old ditch would have been gone, and we could still see parts of it.

Jim: But that black material was really slow to work. We had to manually pick the material apart with our little rock picks.

Dave: These days, we would just plow through that hard-pack with a low-cost high-pressure washer. One of those would have had us going dozens of times faster. As it was, we were only able to dredge a small fraction of our real production capability. Still, for what we were doing, the deposit was building up our gold reserves very quickly.

Dave: These days, we would just plow through that hard-pack with a low-cost high-pressure washer. One of those would have had us going dozens of times faster. As it was, we were only able to dredge a small fraction of our real production capability. Still, for what we were doing, the deposit was building up our gold reserves very quickly.

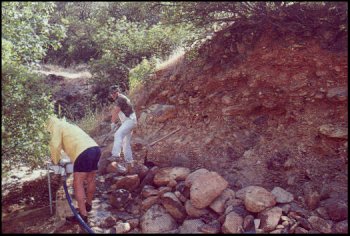

The rich gold deposit also extended up under the stream-bank.

Brian: Towards the end of one day, right on schedule, one of the claim owners arrived to see how we were doing. He didn’t have any trouble finding us and climbing down the hill using our rope. When we showed him the gold we recovered, he about had a heart attack! He was also quite pleased. And you could tell right off that he was reassessing the potential of these yellow-pontooned dredges of ours. When we explained that our deposit was extending up under the bank, he offered to send a tracked excavator over to remove the overburden for us. How’s that for hospitality? We accepted his offer with great appreciation! We would not need his help for several days, because there were still plenty of the underwater portions of the deposit accessible to us.

Dave: Whenever we took the truck anywhere, it was usually Brian who did the driving. As the oldest brother, he had always been the most experienced driver. So he just naturally took up that role in our program. That is, except for the days when Brian returned to camp early to cook dinner. Brian made wonderful spaghetti where he would add in nice hunks of different kinds of vegetables and meat. Everyone liked that.

Since we were doing so well with the gold, we voted unanimously one day to up our daily ration of jelly and milk-honey on the peanut butter sandwiches. This was a big morale-booster, because we were getting tired of these thick peanut butter sandwiches which only had a little sweetener on them.  Canada has this special, fresh milk-honey mix that is to kill for on a peanut butter sandwich!

Canada has this special, fresh milk-honey mix that is to kill for on a peanut butter sandwich!

One morning, we were driving along Pine Creek in the direction towards the claim; and out of nowhere came this mammoth of a she-moose. No horse ever got this big! It came running out from the side of the road, generally in the same direction as we were going, except at an angle to cut us off. She was right on top of us before we even realized she was there! We were driving about 40 miles an hour, and she was going faster. When she bumped the side of the truck, we went into a slide right off the side of the road. Brian managed the slide just right to keep us from toppling over in the truck. The moose just kept on going. There was a pretty sizable indentation in the driver’s side door where the moose bumped into us (nothing more than a nudge).

That moose was not afraid of us a bit. Clearly she was showing us who the boss was. I’m certain she nudged us on purpose. I was in the passenger seat, so I probably got the best look at the animal. There is one point where she dipped her head down and looked right in the window at us, and I remember thinking that she had that very same silly smile as Bullwinkle the Moose in the television cartoons!

The whole emergency was over in 10 seconds and the moose was already long gone. We sat there for a moment in silent disbelief, and then broke out into hilarious laughter.

Brian: Actually, my read was that the moose was trying to knock us off our feet. On that slippery dirt road, had I allowed her to make full contact with the truck, we probably would have spun around and rolled.

Eric: It was late spring. She probably had a young calf around somewhere close and was just trying to keep us away. Good thing we were not walking up the road that morning!

Jim: Work continued pretty-much the same for a few more days. We were limited by how much black material we could pick apart underwater. It was very slow going because the water resistance would only allow you to pick so fast. After a while, my arm would get so tired from the activity, it would go numb. Then it would be someone else’s turn for a while.

Jim: Work continued pretty-much the same for a few more days. We were limited by how much black material we could pick apart underwater. It was very slow going because the water resistance would only allow you to pick so fast. After a while, my arm would get so tired from the activity, it would go numb. Then it would be someone else’s turn for a while.

Taking shifts, we kept two dredges running side-by-side for long hours into the night. Since we were not using them, we removed the other two dredges from the creek downstream, and stored the components in a tent and under our trailer in camp to make the mining components less visible.

Brian: One day, these people drove into camp and launched this big canoe into the lake. They were using an outboard motor for power. The two guys loaded the canoe completely full of supplies and prospecting gear. We sent Jim over to talk with them. They said that once you get off the main road up there in a boat, there is an entire universe of rich mining country that has never even been prospected before!

Jim: The prospectors were friendly. But they were committed to their own program, only talking as they were loading their canoe. It would have been overstepping to ask where they were going, and they didn’t offer anything up on their own. Once the canoe was loaded, they parked their car up in the campground, and off they went. We never saw them again.

Dave: But we watched them motor across the lake, and we were all thinking how that would be a wonderful, romantic way to launch a future prospecting trip…

Eric: Sadie turned out to be a wonderful companion for the whole trip. She also played her important part in warding off dangerous animals. We made her into an outside dog, but she didn’t seem to mind. We depended upon her to sound out if any bears (or moose) decided to visit us during the night. None ever did, probably because she was there. Even though we locked the back door on our trailer when we went to the creek every day, Sadie would remain tied up there so any visitors would have to contend with her in our absence. Nobody ever bothered any of our stuff for the whole trip. We were all glad we brought Sadie along, and I’m sure she was glad to be there with us. We delivered her safely back to my mom when the trip was over.

Eric: Sadie turned out to be a wonderful companion for the whole trip. She also played her important part in warding off dangerous animals. We made her into an outside dog, but she didn’t seem to mind. We depended upon her to sound out if any bears (or moose) decided to visit us during the night. None ever did, probably because she was there. Even though we locked the back door on our trailer when we went to the creek every day, Sadie would remain tied up there so any visitors would have to contend with her in our absence. Nobody ever bothered any of our stuff for the whole trip. We were all glad we brought Sadie along, and I’m sure she was glad to be there with us. We delivered her safely back to my mom when the trip was over.

Brian: Atlin during 1982 was a small, friendly town. My perception was that all or most of the inhabitants were involved with gold mining in one way or another. There were no secrets in that little town. Everyone there had known what we Americans were doing with our yellow dredges. It started off as a friendly joke to them.

Dave: But when we got into the really rich gold, the claim owner, and sometimes his partners, was coming down towards the end of every day to see how we were doing. They were clearly impressed. One day, the claim owner actually made the comment that we were doing better than they were! And that would not have surprised me, because they were having to clear hundreds of feet of overburden to gain access to the very same ancient layer that was directly exposed to our dredges.

There are a number of good reasons why I should not say how much, but we were getting a lot of gold. This was probably our undoing, because news of our discovery must have traveled all around Atlin and elsewhere. The amount of gold we were pulling out of the creek was no joke!

There are a number of good reasons why I should not say how much, but we were getting a lot of gold. This was probably our undoing, because news of our discovery must have traveled all around Atlin and elsewhere. The amount of gold we were pulling out of the creek was no joke!

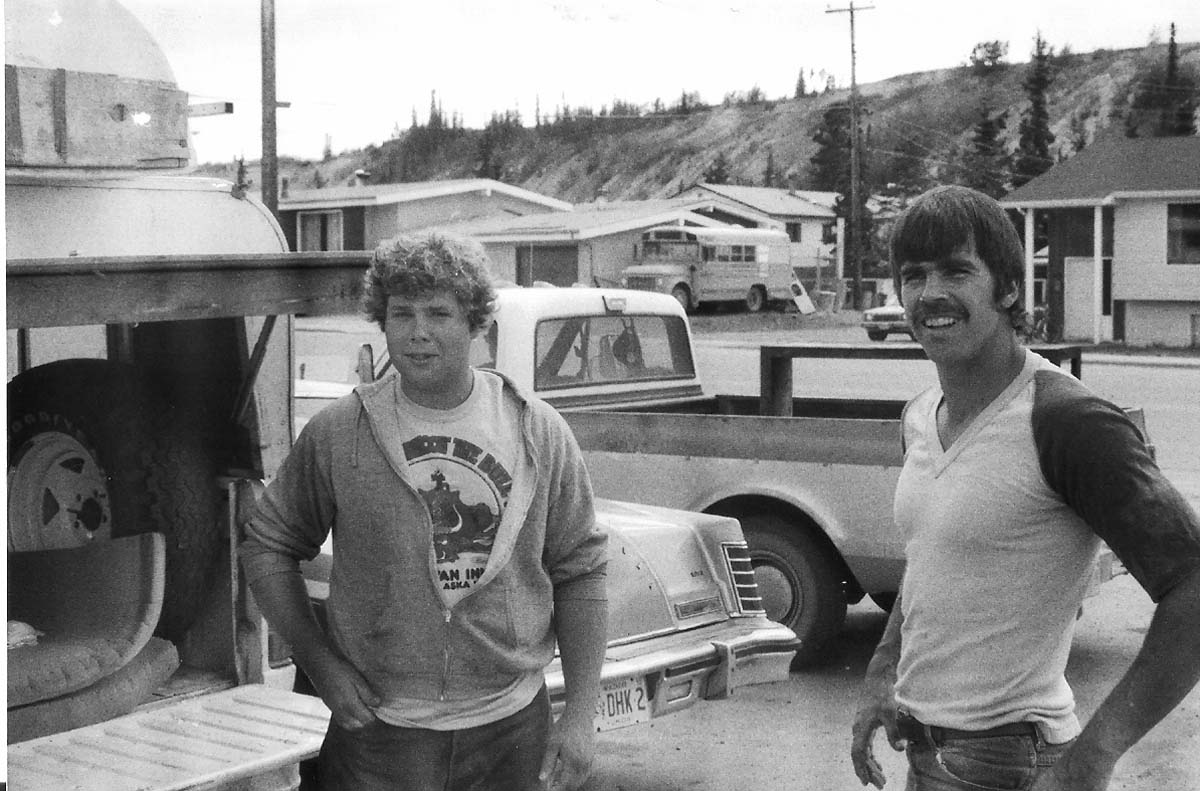

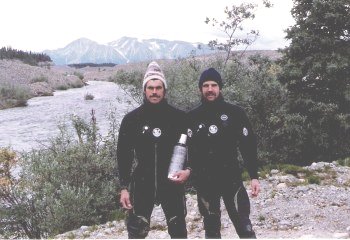

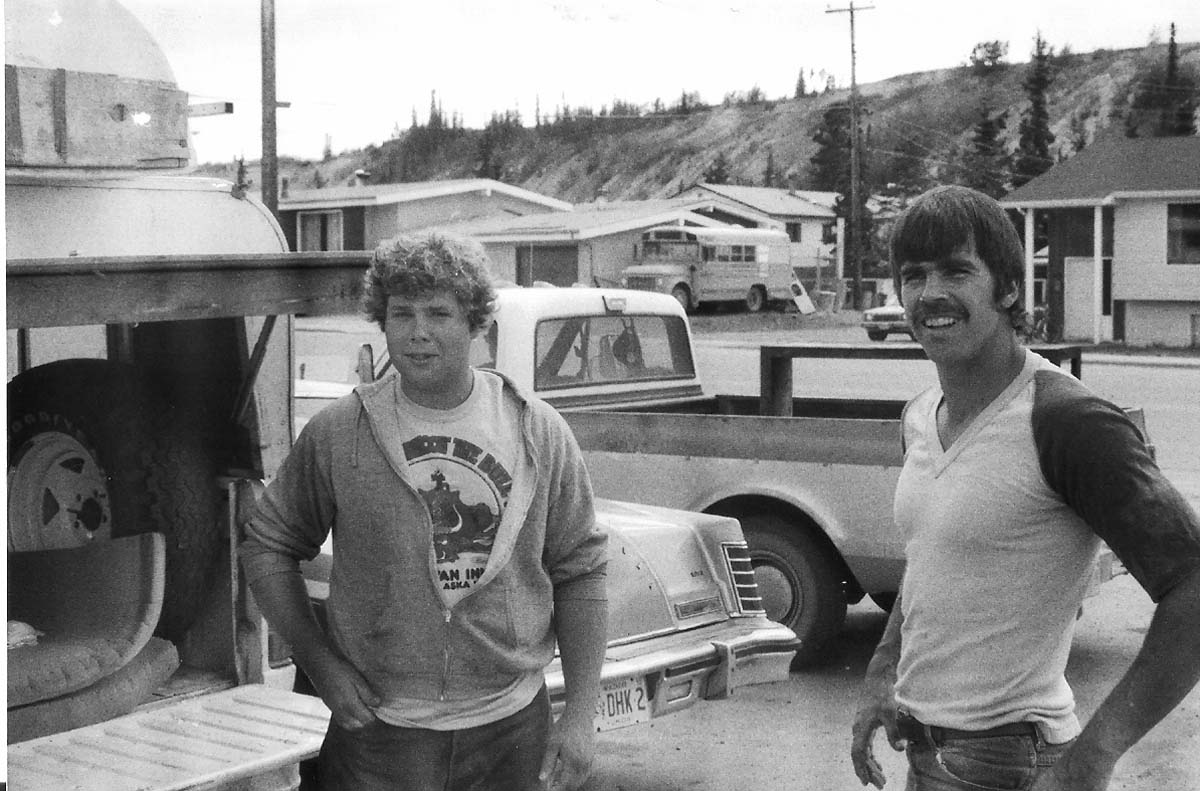

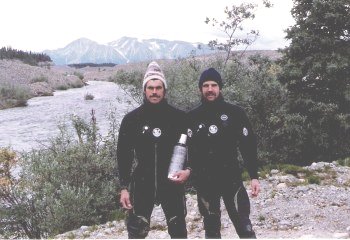

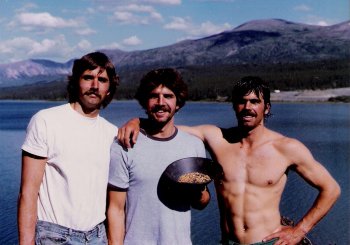

Brian, Dave & Jim showing off a clean-up

Jim: But the gold was not coming for free. Some days we would go to the creek at 7 or 8 in the morning and not return to camp until almost midnight. Dave was pushing us really hard. Nobody was complaining, though. We didn’t know how many days we had left before we were going to get bounced from this rich deposit, so we wanted to make the most of it while we could.

Eric: I was the first one to spot the RCMP patrol car drive up the road one day, going towards our camp. I pointed it out to Jim when it drove by. Jim just rolled his eyes back in this “here comes the problem” look. I nodded to him.

We asked one of the claim owners to snap this picture of the four of us. The picture was taken

at the height of our gold production, about a day before the heat came down upon us.

Dave: When Brian and I came up for a break, Jim and Eric told us the patrol car was probably up in our camp looking for us. We had been expecting trouble from the authorities ever since my visit to Customs in Whitehorse about a week before. In fact, we were surprised that it took them so long to show up!

While we were there on the bank discussing our options, we saw the patrol car drive right past our location, headed down towards Atlin. Our truck was parked behind the claim owner’s gate and out of sight, so the officer didn’t know where we were at. We decided to finish out our day on the creek. While the going was slow with those rock picks, every minute of dredging-time was adding serious gold to our reserves.

Brian: On a notion, the following morning, we sent Jim into Whitehorse on the Honda to sell some gold for traveling money, and to buy a replacement leaf spring for the trailer. It seemed wise to get ourselves ready if a quick departure became necessary.

Jim: That was a long, cold drive on the motorcycle even during the daytime! I was wearing the helmet and my best winter clothes, but I still had to stop frequently to warm myself up. The trip took a long time. When I got to Whitehorse, I sold gold to Dave’s friend first. Then it took a while, but I found a replacement spring and a few more bolts to repair the trailer. Then I made the very long drive back to camp.

Brian: We decided to park the truck even further down the access road by the creek where it would be harder to find in case anyone was looking for us that next morning. This meant we had to make an extended walk up the road in our dry-suits, but we decided it was better to stay out of sight.

Dave and Eric were down dredging when I spotted the patrol car drive by the first time. A little while later, the officer drove back down the road going the other way. We knew in our guts that he was looking for us. You know that deep, aching feeling in your belly when you are in trouble? That feeling was growing in me.

Eric: The patrol car drove by two more times while we were eating lunch.

Dave: I was sitting there on a rock eating a sandwich when I saw my brother, Brian, dive behind a rock to keep from being seen as the RCMP officer drove by. That’s when I knew it was time for us to leave. How things came out on this project was really my responsibility. The original idea was to stop in Atlin and mine gold just long enough to get well again. We had already far-exceeded those expectations. When Brian dove behind the rock, I felt deep internal pang of irresponsibility. I have been living on the edge of some kind of trouble my entire life. It is quite something else to put others through it; guys that are not used to being in trouble with authority.

After just a short discussion, Eric, Brian and I unanimously agreed that we would float the two dredges and all of our support gear down to where we had parked the truck, load everything up, take it all back to camp and stow our gear. The following day, we would go ask for some assistance from the claim owners in dealing with the authorities. It still was not clear to us that we were really doing anything wrong. The claim owners had told us they believed we were within the law.

Brian: As soon as we reached camp, Dave and Eric went right to work on our final gold clean-up so we would not have any visible gold lying around if the officer showed up in camp.

On a hunch that we were in trouble, the first thing I did was load all of our remaining meat from the freezer into trash bags. Then I dumped it all into the pit toilet there in the campground. I also emptied the trash. It was not easy to let go of that meat. But we had switched gears into damage control.

Dave: When the clean-up was finished, I immediately went and hid the latest gold out in the forest. It was a good thing that I did. Because just after I returned, five or six official vehicles came driving into camp. The local RCMP officer was leading the pack. As they were pulling down onto the flat, I told Brian and Eric to just keep taking the mining gear apart and allow me to do all the talking. Brian made some kind of comment like, “Sounds good to me!”

I walked up to the officials as they were getting out of their vehicles. There were several RCMP officers in their unfriendly, no-nonsense mode. It reminded me a little bit of boot camp where the drill instructors always treated us like low-life worms. There were several officials there from the Department of Environmental Control. They were not friendly. There were two officials from the official Canadian Mining Office. The superior of these seemed to be in charge. He seemed like a nice guy that you could talk to. He asked me what we were doing.

I walked him over and showed him that we had broken a spring on our trailer and explained that we had to remove all our gear from the trailer to have a safe place to sleep. He wanted to know if we had been using the mining gear, and I told him some local claim owners had given us permission to play around in the creek. He wanted to know if we found any gold. So I showed him our bucket of concentrates and told him we were doing pretty well. He and his assistant borrowed some of our gold pans and worked some of the black sands down in a wash tub. The boss was impressed, but his deputy told him it was a poor showing. It really was a poor showing!

Brian: While the mining guys were talking to Dave, all the other officials spread out and started looking around at everything in the camp. I remember hoping with my most sincere prayer to the universe that they were not going to go up and look in the pit toilet. They looked in the trash cans there, but they never went into the toilet. Good thing; because if they looked, they probably would have seen all that raw, frozen meat laying in there. That would have been the end of us!

Eric: After a while, both patrol officers came over and started grilling me about the gold we found. I told them we were mainly fishing and that we had only played around in the creek just a little bit. I told them, “There wasn’t much gold.”

It was very interesting; because both RCMP officers seemed really nervous. They each had a walky-talky in their hands, held out in front, like perhaps someone else was monitoring the conversation. Perhaps they were accustomed to handling more hardened criminals than we were.

Dave: The patrol officer then came over and grilled me. This was the local guy from Atlin that was so impolite to us about the motorcycle helmet (riding around out on back dirt roads). He could have just as easily informed us politely that we needed helmets in Canada even when riding out in the forest. Why all the yelling? He was yelling at me now, it was common knowledge all over Atlin that we were recovering kilos and kilos of gold with our suction dredges. I just calmly waved that off as something that happens everywhere we go. “You know how stories get started; there is nothing to it”

In anger, the local RCMP officer informed us they were going to search our truck and trailer. The other officer was going to search our truck. “Go for it,” I gave him permission, and I followed him into the trailer. He looked in the refrigerator; but it was empty, except for some butter and a partial bottle of local milk honey.

He saw the 30-30 and shotgun on the wall and asked if they were loaded. I told him they were not. I watched him struggle with the internal decision to not check the guns. There was ego involved here, and he didn’t want to look foolish trying to open the breaches of unfamiliar firearms to take a look. It was a good thing he didn’t look, because it actually turned out both guns were fully loaded. We had normally been unloading them during the daytime, but I guess we overlooked it with everything else that was on our minds.

I gather that loaded guns would have gotten us into a lot of trouble if they wanted to push it.

While the officer was searching in our internal storage compartments, Brian came up into the trailer and was kind of crowding us. I couldn’t figure out why he did that, but just kept my mouth shut while the officer searched. The officer also felt Brian crowding us and didn’t like it. He ordered Brian out of the trailer. But his search turned up nothing of interest inside the compartment, and soon we were all standing in a group outside.

Eric: I was just a young guy in those days and didn’t have much experience in business. But I was learning a lot from Dave and Brian, both who had received some similar management training during their younger years. They were managing our mining program with the use of a production graph. Every day, after our final clean-up was weighed, they would carefully mark the number of ounces on the graph and connect the line from the previous day. Their management approach was to do whatever was necessary to make the curve move upwards in a steep direction every day. After marking daily results on the graph, we would have some discussion about what we could do on the following day to push the production results even higher. We were always coming up with a new idea. Mostly, it was just about working long, hard hours in the creek. Dave is one of the hardest pushers I ever met. But we were all pushing together to make each production day better and better. There was not a single day we didn’t push the gold production higher than the day before, some days it was double. The production curve on our graph showed nearly a vertical line. Production was so high after the first few days in the rich deposit; we had to add another sheet of graph paper to the top of the first one just so we could log the growing amount of ounces that we were getting every day!

Brian: I was standing there outside the trailer watching the officer go through our stuff, and then had this nightmare awakening that our production graph was taped to the wall inside the trailer right there in plain sight. All of the information was right there on the graph, from the pennyweights we found on our first day, to the kilos we were getting during the final week.

The officer had not recognized the graph on the wall for what it was, yet. The only thing I could think of to do was distract him. So I moved up into the trailer and started looking over his shoulder with Dave while he was searching. This made the officer suspicious, nervous and mad. He told me to get out of the trailer. Shortly afterwards, he followed me out. Unbelievable; he totally missed our production graph that was in plain sight on the wall!

The other officer didn’t find what he was looking for in the truck, either. We were not hiding any gold there.

Dave: Actually our biggest luck was that they did not take the film from our cameras!

Eric: When the searching was finished, the local officer gave it one more forceful try, “We know you guys found at least 100 kilos of gold in the creek; the news is all over Atlin. Either come up with the gold right now or you guys are going to be in a lot of trouble!”

Dave: I looked him right in the eye and told him he could have all the gold we found. “It’s all right there in the bucket of concentrates,” I told him. Everyone present knew we were lying. They declined to take our bucket of concentrates.

Brian: By now, it was pretty late in the day, and the officials from Whitehorse had a long way to go to get home. There is no doubt in my mind that they would have forced us to follow them back to the impound-yard in Whitehorse right then and there, but one of our leaf springs was missing off the trailer. We could not go anywhere. It really turned out lucky for us that we broke that spring!

Dave: After some discussion on his hand-held radio, the local RCMP officer ordered us to get our spring repaired and go to Canadian Customs on the following day. He was talking to me. I was listening very closely, “You will repair that spring and be at Customs tomorrow in Whitehorse.” I said, “Yes sir.”

Eric: You could have picked up their disappointment off the ground when they all drove out of there. They really expected they were going to make the mega-gold bust; it was going to be big news on television!

Brian: As soon as they drove up the road, I tore the production graph off the wall and used the propane stove to burn it. Everyone else just looked on with disbelief that the officers had overlooked it.

Dave: I wasted no time grabbing the bucket of concentrates and flushed them into the lake. That, just in case they changed their minds and decided they wanted to use them against us.

Eric: We didn’t like the way they were always holding their walky-talkies out in front of themselves. It was like they had someone else listening in all the time. We were actually a little worried that they might have bugged the trailer and truck, and perhaps just went a little ways up the road to listen in on us. So we met quietly out in the middle of the campground and made our plan.

Brian: The most difficult part to work out was what to do with all that gold. It was far too much to effectively hide anywhere in the truck or trailer. We strongly considered the idea of hiding it really good and then return to retrieve it later, once the heat was off us. But ultimately, we decided to take the risk of getting the gold up into Alaska that very night where it would effectively belong to us. This was the largest risk we took on the whole trip!