By Dave McCracken

Everything was going normal. My partner and I were using an 8-inch dredge, pumping rich gold from underneath about seven feet of hard-packed streambed. It was just another day in god’s country. Then, without any warning, we ran out of air. “Out of gas,” I thought. As I turned around to go back to the dredge, there it was, upside down, with the engine muffler resting on the bottom of the river!

There are few things more disheartening in gold dredging than flipping your dredge upside down in the river! But if you spend some time talking with experienced dredgers in river-dredge country, you will find a good percentage of operators have experienced turning one or more dredges over at one time or another.

There are few things more disheartening in gold dredging than flipping your dredge upside down in the river! But if you spend some time talking with experienced dredgers in river-dredge country, you will find a good percentage of operators have experienced turning one or more dredges over at one time or another.

Dredges get flipped over because of numerous different factors. One common reason is not having enough flotation under the dredge. Another is having a dredge design where the dredge is not wide enough. Another common problem is in dredge designs whereby the forward-most floats are not tapered enough to help deflect the river’s flow.

Design problems aside, there are two common situations which cause dredges to flip over. The first is when something happens to cause the sluice box to start loading up with the material you are pumping. As more and more material piles up in the sluice box, and then perhaps onto one of the pontoons, the increased weight eventually overwhelms the dredge’s floatation capacity, and over she goes! This can happen in minutes if you are feeding the nozzle at production speed!

The second common reason for flipping a dredge is floating it out into faster water than the design can manage. Every dredge has its limits! A dredge which might float just fine in shallow, slack water might not last five minutes in the faster flow of a river.

As fast water often poses more risk to the dredge than an experienced operator, sometimes you have to find some slack water along the edge of the river where it is safer to float the dredge!

Gold quite often deposits in the fast water sections of a river. Also, because of the faster water, these areas often have less gravel and overburden covering the pay-streaks. Less streambed makes sampling go faster. Consequently, river dredgers often find ourselves dredging in the faster sections of gold-bearing rivers—including white water rapids.

It is difficult enough to overcome the underwater problems associated with fast water dredging. Knocking out plug-ups in the suction hose is particularly difficult. A dredger should not also have to worry about his or her dredge flipping over at the same time. Therefore, a certain amount of dredge modification might be necessary on any store-bought dredge before it is used under fast water conditions.

Normally, dredges are modified for fast water by adding more flotation—sometimes to the sides, sometimes to the forward-part of the dredge.

Here’s something important: Additional side flotation tends to make the dredge more stable from side to side and generally prevents the flipping problem. However, additional side flotation enormously increases the dredge’s water drag in the fast current. This puts a great deal of pressure on the tie-off lines, and it also makes it more difficult to get on and off the dredge, or work around the dredge (knocking out plug-ups) without getting swept down river. This is because the additional drag directs a larger volume of water around the sides of the pontoons.

It is usually more difficult to mount additional flotation as an extension of the front of your dredge; but we have found in our own operations that this is the better overall modification for several reasons. Reduced water drag is very important in swift water conditions. More floatation up front helps prevent the dredge from doing a submarine dive! Also, the additional platform in front of the dredge provides more space to place support gear on your dredge. And, in the case of larger dredges, if you should ever want to mount a winch on the front of your dredge, the extra flotation and frame will already be in place.

But you do not need to be in fast water to flip a dredge over. As mentioned above, a very common reason for a dredge to flip over during operation is sluice box load-up. This is when rocks and gravel overwhelm the sluice box, start flowing over onto the decks, and eventually cause the dredge to list over to one side and flip. If you have a water-flow problem with your recovery system, the problem must be resolved before you operate your dredge without someone at the surface to keep an eye on it. The key is to get enough water-flow to keep all of the rocks and material moving through and out of the recovery system. We always make sure we have a little more flow than necessary, because we choose not to hire a dredge tender to stay on deck.

Occasionally, even with a dredge which is set up perfectly, just the right rock can lodge in the sluice box and create an obstruction. Then that single rock can be the cause of a sluice box load-up. If not caught in time, the load-up can collect enough weight to flip the dredge over. This is why I say many experienced dredgers have had the fun (not) of flipping a dredge. Helpful hint: It never hurts to look back every once in a while to make sure your dredge is floating alright!

Tying off the dredge properly in swift water is also an important factor in preventing a flip-over. Obviously, you do not want your dredge sitting broadside in a fast current! It is a matter of applying Murphy’s Law: you must observe the water-flow and its effect on the dredge. If it looks chancy, come up with another plan.

When a dredge is flipped over, you usually lose all of the items that float. If the river is swift, these things are usually quite some distance down river before you get back up on the bank and remove your dive gear. I will never forget the time we came up from a dive several years ago just in time to see the five-inch dredge that was operating just downriver from us was underwater and

hanging by just one pontoon. The guy was dredging when we started our dive, so we assumed he was still underwater, pinned by a rock, or perhaps knocked in the head by the dredge when it flipped over, or something. Because the owner of the dredge was nowhere to be seen!

However, it turned out that when the dredge flipped over, the dredger came to the surface and saw his other pontoon going downstream fast. He off-loaded his dive gear and swam through three separate sets of rapids trying to catch the pontoon. These were the very substantial rapids on our Mega Hole claim at K-15A! He never did catch up with the pontoon. He showed back up at the dredge about 45 minutes later, exhausted and demoralized. We already had dragged the remainder of his gear out of the river. Using my jet boat, several hours later, we located his pontoon about eight miles downriver in a back eddy. It only took him several days to get his dredge running again. He installed extra flotation to prevent further such incidents.

When a dredge is flipped over, after it is set right-side-up again, the water needs to be completely removed from inside the engine and hookah air compressor. We usually do about half a dozen oil changes, starting the engine for a few seconds each time, to remove more water. As long as the oil keeps turning milky, it is necessary to keep changing it.

It is not as hard on an engine if it is not running when it goes underwater! Sometimes it is necessary to remove the electrical components and blow them out with air or replace them altogether in order to get spark at the spark plug again.

The air compressor must have all water removed from inside, as well as the intake air filters and air lines. If the compressor was running when it was submerged, it will be necessary to pull out the reed valves and make them straight again or replace them.

And of course, if you were dredging gold, some or most of that will have been lost from your sluice box when it flipped over. So, you will have to decide whether it is worth going through your cobble and tailing piles to retrieve it. It usually is not worth the effort, because you can get more gold by just continuing forward on your pay-streak.

One important dredge modification worth doing is to secure the sluice box to the frame or deck of your dredge so it will not flap free in the current should the dredge become flipped over. This prevents the box from being damaged or lost altogether. It also makes it a heck of a lot easier to get the dredge flipped back over.

One important dredge modification worth doing is to secure the sluice box to the frame or deck of your dredge so it will not flap free in the current should the dredge become flipped over. This prevents the box from being damaged or lost altogether. It also makes it a heck of a lot easier to get the dredge flipped back over.

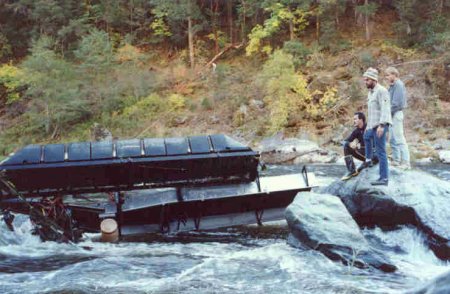

At the end of last season, one of our local commercial dredgers was trying to winch his dredge up through a particularly difficult section of rapids on our K-17 property along the Klamath River. He was trying to test a potentially-excellent hot spot that no one else had ventured into, yet. The spot looked great; many pounds of gold were recovered just upstream and just downstream. The spot is probably still loaded with gold!

He was moving the dredge alone, using a power winch anchored to the streambank some distance upstream. Just as he was almost around a large rock, the outside edge of his dredge took a dive and the dredge flipped over — just like that. This is the way it usually is in fast water; when something goes wrong, it happens quickly and decisively. Usually, there is little time to do anything effective about it.

Besides all of the damage to a dredge, the loss of support gear, and the loss of production time, there is also a large amount of embarrassment which goes along with having a dredge floating upside down in the river!

Besides all of the damage to a dredge, the loss of support gear, and the loss of production time, there is also a large amount of embarrassment which goes along with having a dredge floating upside down in the river!

Once we found out about his problem, we put the word out, and experienced New 49’er members from the area converged on the site to help our friend. It is no small task to right an eight-inch dredge in fast water! The images in this article were captured as we made it happen.

First, we had him winch the dredge around the rock and pull it into slower moving water. This did not help the equipment much, because his sluice box was dangling in the current and dragging along the river-bottom. His engine was also dragging the bottom. Not good!

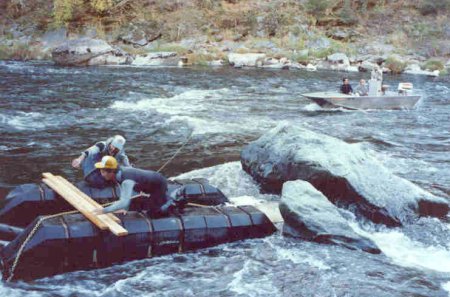

We spanned the bottom of his pontoons with some beams, and then cranked his sluice box back up to his deck before trying to winch the dredge back over.

Then, we had several divers go under the dredge and use chains and a come-along to lift the sluice box up and secure it to the deck. We used a boat to set up an electric winch on the far bank. We secured the two outside corners of the dredge to the bank on the close side of the river. We secured the winch cable to the opposite corners of the dredge and we winched the dredge over. What a mess the dredge was! Since it was late fall anyway, this pretty-much finished the dredger’s season. Miners are a hardy bunch; he returned the following year, better and smarter than ever!

Then, we had several divers go under the dredge and use chains and a come-along to lift the sluice box up and secure it to the deck. We used a boat to set up an electric winch on the far bank. We secured the two outside corners of the dredge to the bank on the close side of the river. We secured the winch cable to the opposite corners of the dredge and we winched the dredge over. What a mess the dredge was! Since it was late fall anyway, this pretty-much finished the dredger’s season. Miners are a hardy bunch; he returned the following year, better and smarter than ever!

The moral of the story is that a little prevention goes a long way. Another thing: we are dealing with the forces of nature. We use our observation and judgment. We take some chances and we are not always right. Murphy lives! And, when he wins a battle, it doesn’t mean he has to win the war. There is always another day and another opportunity.

Another thing: We are dealing with the forces of nature. We use our observation and judgment. We take some chances and we are not always right. Murphy lives! And, when he wins a battle, it does not mean he has to win the war. There is always another day and another opportunity!

By Dave McCracken

The main barrier to overcome is the psychological impact from the uncertainty of whether or not you are going to find an acceptable gold deposit.

During the past five years, we have had an opportunity to work with hundreds upon hundreds of different gold miners, and we have realized many different things about how to approach a gold mining operation to improve a person’s chances of success. One of the things we have realized is that some people become so serious about a mining operation that they lose track of the fact that the operation is simply a game.

During the past five years, we have had an opportunity to work with hundreds upon hundreds of different gold miners, and we have realized many different things about how to approach a gold mining operation to improve a person’s chances of success. One of the things we have realized is that some people become so serious about a mining operation that they lose track of the fact that the operation is simply a game.

All games consist of a goal, a means to achieve the goal, and barriers or problems in the way of the goal’s achievement. And, of course, the GAME consists of overcoming the obstacles and achieving the goal. Football is a game; basketball, soccer, everybody knows these are games. What some people fail to realize is that your job, raising your family properly, getting through life successfully, and even gold mining–are all games, too. Each of these games have their own unique set of problems to overcome.

Because of the seriousness and importance of winning, sometimes we lose track of the fact that these different aspects of life are a game. The importance of winning simply requires that we play the game harder.

It is much easier to win at a game when you know what the game is that you are playing.

Gold mining is a game in which the obstacles and problems to overcome are not, generally, other people or other teams as in the game of football. The main obstacle to overcome in gold mining is the UNCERTAINTY of where acceptable gold deposits are located.

The best goal, of course, is to find lots of gold–enough to resolve your financial or emotional needs. I say emotional because some people are not in gold mining necessarily for financial gain. One person’s goal might be to continuously recover enough gold to support his family and the lifestyle. Another person might want to find enough gold to retire in luxury. Someone else might just like to find any amount of gold. Each individual will have his or her own goals. Once one goal is nearly achieved, a person naturally tends to set a higher, more difficult goal. One of the interesting things about gold is that you never seem to have enough of it–even if you have a lot compared to the goal you set for yourself some time ago! Therefore, as a miner gets better, he or she tends to elevate the goal higher and higher.

The means of achieving the goal in gold mining is by applying mining and prospecting techniques with available mining equipment on gold bearing locations so that you can to locate and recover valuable deposits.

- The Basics of Successful Gold Mining, Part 1

- The Basics of Successful Gold Mining, Part 2

- The Basics of Successful Gold Mining, Part 3

The equipment is readily available. There is nothing difficult to understand about the techniques and procedures. The main difficulty is NOT KNOWING WHERE THE GOLD IS. This makes gold mining unique, in that the main obstacle to overcome is not an external, material or barrier–as in most games. The main barrier is the psychological impact of the uncertainty of whether or not you are going to find an acceptable gold deposit.

In reading this, you might find yourself feeling that you are dedicated and strong enough, that you have all of the discipline needed, that you have plenty of emotional fortitude, and that you are smart enough to overcome any psychological doubts which may arise in your own mind during the course of a sampling operation. We all have this, and we are all potentially strong enough to persevere. However, there are also negative voices in our heads–which can become quite strong when we are directly confronted with difficult situations. Sometimes we forget about these voices during times when we are not confronted by difficult situations!

None of us are super-beings. We are human. We all have our personal limitations–which are set by ourselves. This happens when we make decisions that we can’t do something, or that we don’t want to do it. A person takes up running and decides he can only run two miles. Does that mean he cannot run a step further than two miles? Of course not. The person could run twenty miles if he set his mind to it. If I did not learn another thing in SEAL training from my navy days, I learned that you can always take at least one more step. This is true in any aspect of life–in any endeavor; you can always do it a little more or a little better.

But, when we get close to a limitation which we have already set for ourselves, we run smack into the negative voices in our heads which we have ourselves identified with. “I can’t do it!” Just because the voice says we can’t doesn’t mean we can’t. We can, and by doing so, a person becomes stronger.

The problem in gold mining is different than in most other games. If you were cutting firewood for money, the barriers to overcome in the game would be the physical challenge of cutting down trees, sawing them into rounds, splitting the rounds

up, loading them in a delivery truck, hauling them to a location, selling them to someone, and maybe stacking the firewood on the buyer’s back porch. The easy thing about this challenge is that you are working with a reality that you can see all the way through the cycle. The wood is there. It is just the physical work of getting the wood onto the buyer’s back porch–that is, as long as you have a buyer.

Gold mining is different. The gold is not there until you find it. Yet, it’s really not that the gold isn’t there. When we see other miners recovering gold out of commercial deposits on the same river, we know there are more commercial deposits to be found. The problem is that we might not be sure that we are going to find them.

And, it’s not that the procedures and techniques for finding gold deposits are difficult. We know that gold, because of its weight, tends to travel along its own narrow path in the river. We know that pay-streaks (gold deposits) form in their own unique locations along the gold path–where water velocity slows down during major flood storms. We know these pay-streaks form quite regularly along a gold-bearing waterway. And, we know that prospecting consists of digging or dredging sample holes in an attempt to locate the gold path and the pay-streaks. None of this is difficult to understand and apply.

The difficulty is in the uncertainty–and this is the main barrier to overcome in the game of gold mining. We see a fair percentage of people who have themselves psyched out and talked out of it, even before they finish their first sample hole. Why is this? They have adequate equipment. They understand the procedures. They can confront the physical work. Why do they quit so quickly? It is because they don’t understand who the real opponent in the game is.

If it were a game of football, would they quit after the first play of the first inning just because the opposing team looked stronger? Not if the players have any degree of personal pride in being a football team. Yet, quite often in many games, the opposing players try to psyche-out the members of the members of the other team. A demoralized team is easy to conquer! More likely, a serious football team would psyche themselves up in an attempt to win over a stronger opposing team.

What people don’t realize is in the game of gold mining, you are really playing with and/or against yourself. It is your own inner voices which you listen to and decide whether to quit early, or to pour on the steam even harder to find the gold deposits you are looking for. When a person quits in gold mining, it is often because he has psyched his or her own self out.

I can understand quitting when your legs are busted and you are on your last breath of air. This is understandable. But, to quit gold mining because you have talked yourself into the idea that you are not going to find any gold just means that you don’t understand the game. Basically, in this case, you have lost to your own inner voices.

understandable. But, to quit gold mining because you have talked yourself into the idea that you are not going to find any gold just means that you don’t understand the game. Basically, in this case, you have lost to your own inner voices.

There is a fantastic feeling of self-accomplishment when you succeed in gold mining. A professional football player, when retired, will look back and remember certain games that were won. He probably won’t be thinking much about the money he made. He probably won’t be thinking of the easy victories. He will be thinking about the games his team was losing, and how the team pulled together, raised themselves up, and won against all odds. These wins are cherished, because they occur when a player, or a team of players, reach down inside and create the necessary additional energy and willpower to overcome large barriers and obtain the goal after all.

Success in gold mining brings about this same kind of intense emotional satisfaction–only better or different in the fact that you usually accomplish it on your own. You generally don’t have a team of other players helping you to make a touchdown in the game of gold mining.

Success in gold mining brings about this same kind of intense emotional satisfaction–only better or different in the fact that you usually accomplish it on your own. You generally don’t have a team of other players helping you to make a touchdown in the game of gold mining.

Like it or not, gold mining is similar to a game of solitaire. You are playing the game with yourself as your teammate, and possibly with yourself as the main opposing force. you have a chance to overcome the little negative voices in your head that tell you to quit–not just in gold mining, but also in the other aspects of your life. Each time that you persevere and finish that next sample hole properly, despite the inner voices which tell you there is no gold in that location, not only do you get that much closer to the gold deposit you’re looking for, but you also grow stronger as a person. And, in the end, this is worth more than gold.

- Here is where you can buy a sample of natural gold.

- Here is where you can buy Gold Prospecting Equipment & Supplies.

- More about the right approach in mining

- More about how to prospect for gold

- Schedule of upcoming events

- Books and Videos By Dave McCracken

“Suction dredging for gold is the most productive means of recovering high-grade gold deposits that I know of. The reasons for this are covered in the following stories.”

- Today’s Best-selling Books & Videos on How to Find Gold

- Suction Dredging for Gold

- Fast Water Dredging

- Teamwork in Production Gold Dredging

- Outfitting a Suction Dredging Project

- Boulders & Winching Techniques

- Double-screen Classification on Suction Dredges

- Underwater Suction Mining Without the Use of a “Suction Dredge!”

- Underwater Blow Mining in California Without a Suction Dredge!

- Using a Swing Line to Anchor an Extended Suction Hose Further Out Into the River

- Dredging is Hard Work

- Dredging Tips

- Watch Out for the Bedrock

- Knocking out Plugups

- Your Airline is an Extension of Your Life

- Flipping Dredges Over

- Cold Water Dredging

- Moving Boulders with a Floating Winch

- Shoot Your Gold

- Getting Your Dredging Equipment Ready for the Season

- Pickle That Engine

- Rocks don’t Weigh as Much When Submerged Underwater

- Trapped!

“You can also find gold out in the deserts and other dry areas where there is little or no water available.”

By Linda Montgomery

I have found it is not necessary, during weekend or vacation gold mining trips, for women to be resigned to the camp cook and dish washer position. There is an easy, hassle-free way to spend your time and have it turn out uniquely rewarding at the end of the day. This method is called “crevicing”. It requires few tools, no back breaking work and can be enjoyed by the whole family. My kids and I have creviced in desert dry washes as well as along streams and rivers. The final panning of the material we’ve recovered has always kept us going back for more!

Crevicing gets it’s name from the cracks and crevices found in exposed bedrock. These are known gold-catching areas. It is amazing how deep gold can settle inside these cracks. The job of crevicing involves breaking the crack open wide enough to allow you to get out all the material that it contains. This isn’t hard. Within a short time you can become a pro at it. The tools of the trade vary. it’s best to have a chisel, rock pick and a gold claw. A bucket is needed to put your material in, along with a #4 classifier. If you classify at your work site, you will not have such a heavy load to lug back to camp. Add a tablespoon to your tools for scooping out material in places where your hand won’t fit.

The very best piece of equipment you can add to your operation is one of the several models of motorized vacuum suckers now available on the mining market. It is not a necessity, but there is no comparison to the ease and thoroughness of using one. These vack machines are extremely lightweight and strap to a pack frame for carrying on your back. Instead of spooning or scraping out your material, you can simply vacuum it up. These motorized vacuums are also good for sucking flood gold out of moss on high water rocks. This is probably the easiest job of all.

suckers now available on the mining market. It is not a necessity, but there is no comparison to the ease and thoroughness of using one. These vack machines are extremely lightweight and strap to a pack frame for carrying on your back. Instead of spooning or scraping out your material, you can simply vacuum it up. These motorized vacuums are also good for sucking flood gold out of moss on high water rocks. This is probably the easiest job of all.

Here is where you can find a special offer on the world’s best vack machine.

But do not fret, if you don’t have one. When I started crevicing, I used a hammer and a screwdriver!

After you’ve gathered your tools together, hike up the river or along a dry wash, wherever you happen to be. Look for low bedrock exposure, because gold is heavy it tends to concentrate more readily in the low spots. Preferably find a crevice in the rock running toward the river instead of along it. These usually catch more gold. Remember also, the bigger the crack, the larger the gold that could be trapped inside.

Start working by loosening everything inside the crevice with your gold claw or screwdriver. Scrape it out and into your classifier on top of your bucket. Chip around any rocks jammed in the way with your chisel until they come free and you can pull them out. Sometimes you can knock off the sides of the crack to widen it by hammering. This enables you to work farther and deeper into the crevice. If you reach a point where you cannot fit your hand, use your spoon; scraping away until the crevice is clean.

This type of bedrock is over 500 million years old. It’s origins come from the ancient mountains that used to be here. Quite often it appears harder than it is; but if you keep digging and scraping, it is actually soft enough to keep breaking away.

Take everything! Moss, sand, dirt, anything that you can loosen. Clean the crevice out as much as possible or as far as you can reach. If you finish one spot and have not gathered enough material in your bucket, move to another spot.

The hardest part about this whole method of mining is carrying your material back to camp. You can regulate this to suit you. Or, if you have kids or a partner, you can share the load. That is, unless water is near the place where you are working. In that case, you can either pan or sluice your pay-dirt right there.

Crevicing is fun and rewarding for the whole family. You will probably recover lots of fine gold and once in awhile a nice nugget or two. Your back will not hurt and you will not be dog tired when you are through, either! If suction dredging for gold is not your cup of tea, and you do not want to spend extra dollars on other equipment, crevicing may be just the thing for you. No noisy engines, no gas to haul, nothing to break down. Just peace and quiet, and the enjoyment of a job well done.

- Here is where you can buy a sample of natural gold.

- Here is where you can buy Gold Prospecting Equipment & Supplies.

- More About Gold Prospecting

- More Gold Mining Adventures

- Schedule of Events

- Best-selling Books & DVD’s on this Subject

“Crevicing, both above and below the water, and vack-mining, especially in and around the moss along the edges of an active waterway, are one of the most popular methods our members use to recover gold.”

By Dave McCracken

Using the Le Trap Sluice to make your

final clean-up go faster.

Because we have so many innovative, active gold dredgers and small-scale miners on the Klamath River, I don’t recall exactly who came up with the original idea of using a Le’ Trap sluice for final cleanup. When I first heard of it, I had reservations. We have been improving the fine gold recovery on our dredges for years. I was afraid the plastic sluice in final cleanup would lose a large percentage of the extra-fine gold that we are now recovering in our dredges. However, upon close inspection, this proved not to be the case.

One of the most time consuming jobs on any serious gold dredging activity is the final cleanup procedure of separating your gold from all of the other heavy black sands and materials which are also recovered by the dredge. My personal operation is utilizing two eight-inch dredges. We are working in an extensive fine-gold paystreak, which requires us to cleanup about two-thirds of our recovery systems at the end of each day. This amounts to about three five-gallon buckets of concentrates to process. In the past, we have utilized spiral wheels and just about every other kind of cleanup device available to process our final concentrates down to our final gold product. Always, with any of these devises, we succeeded in reducing the amount of concentrates down to about a handful, which we would then process with mercury amalgamation.

During the last several years, we have been using a professional shaker table to work our concentrates down. We found that the shaker table was faster than spiral wheels and the other devises we had tried. Even so, with three five-gallon buckets to process, we were spending several hours each day just running our concentrates across the table. Once the concentrates are worked down to a handful-sized amount, the final amalgamation process only takes about a half hour. In other words, the most time consuming job had been to work the concentrates down to just a small amount.

Shortly after we heard that the Le’ Trap sluice was being successfully used, there were other dredgers on the Klamath, dredgers who knew what they were talking about, starting to rave about how fast and effective the sluice was for final cleanup. Lots of people were starting to use the new system. Consequently, we decided to give it a try. We were quite impressed with the results!

Basically, the system is quite easy, and also quite inexpensive. The Le’ Trap sluice retails at about $90. When used in conjunction with a dredge, no further equipment or pumps, etc., are needed, except a garden trowel of some kind to shovel concentrates with.

We start our dredge and run it just over idle speed to get a small amount of water moving through the primary dredge sluicebox. Water flow through the Le’ Trap sluice can be adjusted by engine speed, or by placing any flat objects under the tail end of the sluice. If you do not have enough water flow, you will notice the black sand does not move through the sluice with any regularity. Rather, it tends to pack up and bury the riffles. In this case, you will notice your gold sitting on top of the black sand, rather than inside the riffles.

If you have too much water flow, you will notice that the black sand flies through the box, with little chance to make contact with the riffles. There is plenty of margin for error. Ideally, with the proper water flow, as you feed concentrates into the sluice with a garden trowel, you will watch the black sands work their way down the box in an orderly procession. The flat, smooth section of the box ahead of the riffles allows the pieces of gold to trail along just behind the black sands. And the riffles stay somewhat clean and open. You can watch the flakes of gold wash down and drop into them.

When done properly, you will find 90% of your gold trapped behind the first four or five riffles. A few pieces, just a few, will work their way further down. But, almost none make it all the way out of the Le’ Trap sluice. We were working with several ounces of very fine gold per day; and to test the system, several times we brought all of the tailings home to see what we had lost from the Le’ Trap Sluice. It was never more than a half of one percent of our total gold recovery.

Sluice. It was never more than a half of one percent of our total gold recovery.

And, really, we didn’t even lose that gold, because it simply ran back into our dredge recovery system.

The Le’ Trap sluice is a one-piece molded unit which has a unique set of very efficient short riffles which seem to suck the gold right out of the water’s current. Cleanup of the sluice is simply a matter of tilting it up and dumping it into a tub or gold pan. The final product ends up not being much more than a handful of gold and your heaviest concentrates. Needless to say, this is much easier to deal with, rather than having to lug several heavy buckets of concentrates up the hill to our vehicles!

The main ingredient that we saved with this new cleanup system is time. We were able to feed the Le’ Trap sluice about twice as fast as our commercial shaker table. And, we only needed to screen the concentrates down through a quarter-inch screen using the Le’ Trap sluice, rather than through a quarter-inch mesh screen, then an eighth-inch screen, and then a 20 mesh screen to use the shaker table. This saved a lot of time in itself.

Plus, the system was so simple to use, we purchased a second sluice and used one on each dredge to cut our cleanup time in half again!

Since it only takes one person to feed the Le’ Trap sluice, we would put everyone else to work with end-of-the-day organizational activities while the concentrates were being run. Things like putting airlines and weight belts away, transferring used gas cans off the dredges, minor equipment repairs, etc. About the time that everything is put away and finished for the day, the concentrates are also finished, and we only have a half-hour of finish-up when we get home. This is a HUGE improvement over our old systems for final cleanup.

While smaller dredges have lesser amounts of concentrates to deal with at the end of the day, the time it takes to work them down usually is considerable, even on a three-inch dredge operation. That is, providing you are recovering worthwhile amounts of gold, especially fine gold. I don’t see any reason why the Le’ Trap sluice could not benefit any dredging operation where the dredge sluice is wide enough to allow the Le’ Trap box to fit inside.

We will be using this system in our operations during this upcoming season, and in future seasons until someone comes up with something better and faster. Anyone want to buy a good commercial shaker table?