By Dave McCracken

“When to do a clean-up”

Some miners like to “clean-up” their sluice boxes after every hour of operation. Some prefer to do clean-up at the end of the day. Others will go for days at a time before cleaning up. This is all a matter of preference and seldom has much to do with the actual needs of the sluice box.

Some miners like to “clean-up” their sluice boxes after every hour of operation. Some prefer to do clean-up at the end of the day. Others will go for days at a time before cleaning up. This is all a matter of preference and seldom has much to do with the actual needs of the sluice box.

More commonly these days, a dredger only cleans-up the “high-grade” section of riffles in his or her dredge after each sample or at the end of a production day. That is a special small section of riffles which catch most of the gold near the head of the sluice. The full recovery system is usually only cleaned-up when enough gold has accumulated to make the effort worthwhile, or it is time to take the dredge out of the water.

There is a method of determining when a sluice box needs to be cleaned up, so that you can keep it operating at its utmost efficiency. If the majority of gold is catching in the upper-third section of the sluice box, then the recovery system is working well.

There is a method of determining when a sluice box needs to be cleaned up, so that you can keep it operating at its utmost efficiency. If the majority of gold is catching in the upper-third section of the sluice box, then the recovery system is working well.

After a sluice box has been run for an extended period of time without being cleaned, the riffles will be substantially concentrated with heavy materials behind them. Sometimes an abundance of heavily-concentrated material in a sluice box can reduce the efficiency of the riffles. This is not always the case. Much depends upon the type of riffles being used and how they are set up in the box. The true test of when a set of riffles is losing its efficiency because of being loaded down with heavy concentrates is when an important amount of gold starts being trapped further down the length of the box than where it normally catches. When this occurs, it is definitely time to clean up your box. Otherwise, clean the box when you like.

Expanded-metal riffles, being short, will tend to load up with heavy black sands faster than the larger types of riffles. Still, a large, visible amount of black sand being present is not necessarily a sign that you are losing gold. Gold is about four times heavier than black sand. As long as there remains fluid action behind the riffles, the black sand might have little or no effect upon gold recovery. The best way to evaluate your recovery system is by direct observation of where the gold is being trapped.

DUMPING OFF

The concentrates which have accumulated in a sluice box can be removed by unsnapping the riffles, carefully removing the carpet underlay, and washing everything into a washtub or bucket. The contents can easily be rinsed out of the carpet underlay inside the washtub.

A medium-wide plastic putty knife can be very helpful in removing lingering concentrates from the high-grade section of a sluice box when that is the only place in the recovery system being cleaned-up.

The concentrates can then be screened into another wash-tub or into a bucket, depending upon what type of screens you are using. Classification of the concentrates into several sizes will allow you to process each more efficiently. The size-classifications that you want to use will depend largely upon how you will process the final concentrates. No matter how you process the final material, you almost always want to begin with a ½-inch or ¼-inch screen, just to eliminate all the larger-sized material from your concentrates. The following video segment demonstrates this preliminary screening, reminding you to carefully remove any gold nuggets which stay on top of the screen before discarding the larger-sized material:

There are several types of final clean-up devices on the market which can help you process the final concentrates, including different kinds of wheels, bowls and miniature sluicing systems. They all work pretty well when set up properly. Here is a video sequence demonstrating the use of a gold wheel to facilitate final clean-up:

Each device has its own instructions about the proper classification-size of concentrates for optimum performance. So you will want to buy or make your screens accordingly. The following video sequence demonstrates a second screening through a common sieve about the size of window screen – which is about normal for splitting concentrates into two sizes:

In my own operations, when we accumulate more than just a small amount of concentrates to clean-up, we have had very good results by first running the concentrates through a plastic Le Trap Sluice. First, though, we screen the concentrates through 8-mesh or 12-mesh screen to remove larger material. The following video sequence shows the Le Trap being used to help with a final clean-up:

Or, rather than use a special device (wheel, bowl, etc), you can work your concentrates completely or nearly down to the gold with the use of a gold pan. In this case, I would suggest that you first classify the material through 8-mesh (8 openings per linear inch) and then through 20 mesh (20 openings per linear inch) screens to break it up into three sizes: 1) the material which stays on top of the 8-mesh screen; 2) the material which passes through the 8-mesh screen but stays on top of the 20-mesh screen; 3) and the material which passes through the 20-mesh screen.

Under normal circumstances, the larger two classifications of concentrate will pan down to gold by themselves quite fast. Because of this, even a final clean-up device is usually only used in the field on that material which will pass through the smallest classification screen.

I have thoroughly demonstrated the panning process in a separate article, so I won’t repeat that here.

FINAL DRY SEPARATION

These final clean-up steps can be done at camp, preferably in a dry environment, where the wind is not blowing much and where there is a table top or some other flat surface available to you for a work space.

Important: Before you do the first step of this process, it is best to work your concentrates down as far as possible, to remove all of the black sands that you possibly can. The more black sand you can remove while the material is wet, the less you have to deal with after it is dried. Sometimes you can remove more black sand with the careful use of a finishing pan (small steel gold pan about 6-inches in diameter) inside of a small wash tub.

Important: Before you do the first step of this process, it is best to work your concentrates down as far as possible, to remove all of the black sands that you possibly can. The more black sand you can remove while the material is wet, the less you have to deal with after it is dried. Sometimes you can remove more black sand with the careful use of a finishing pan (small steel gold pan about 6-inches in diameter) inside of a small wash tub.

A Gold Extractor will allow you to work all of your gold down with no loss, and only about a tablespoon of black sands remaining.

Important Note: The best finishing device I have ever seen for working concentrates down to only about a tablespoon of remaining black sand, with zero loss of your gold, is called a “Gold Extractor.” Once your final concentrates are worked down to a very small amount of black sand remaining, you are ready to go on to the next step.

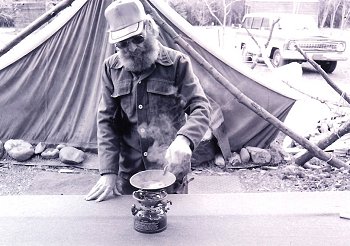

STEP 1: First dry out your final concentrates. This can be accomplished by pouring them into a small metal pan (finishing pan is best) and slowly heating them over an open fire or gas stove-whichever is at hand.

STEP 1: First dry out your final concentrates. This can be accomplished by pouring them into a small metal pan (finishing pan is best) and slowly heating them over an open fire or gas stove-whichever is at hand.

Dry out the concentrates.

CAUTION: Heating the concentrates from a gold mining program should not be done inside of a closed environment. Heating should be done outside and/or in a well-ventilated location, where any and all vapors given off by the various steps will be swept away from you and other bystanders.

You do not want to heat the concentrates too much at this stage. This is because they may still contain some lead. Excessive heat can melt the lead onto some of the gold within the concentrates. Pay attention to heat just enough to thoroughly dry out your concentrates. Be careful that boiling or bubbling during heating is not allowed to spatter gold out of the pan. The following video segment demonstrates this step:

STEP 2: Once the concentrates have cooled enough that they can be handled, they should be screened through a piece of window screen (about 12-mesh). A small piece of window screen, about 6-inches square, is handy to use for this purpose.

STEP 2: Once the concentrates have cooled enough that they can be handled, they should be screened through a piece of window screen (about 12-mesh). A small piece of window screen, about 6-inches square, is handy to use for this purpose.

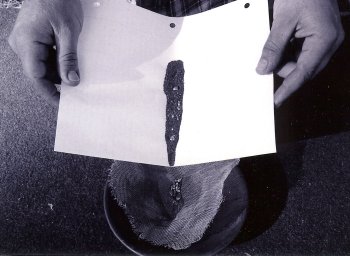

STEP 3: Take the larger-sized concentrates (the material which would not pass through the window screen), and pour them onto a clean piece of paper. If there is a lot of this sized concentrate, this step will have to be done in stages, handling a little at a time. Once the concentrates are poured onto the paper, it is easy to separate the pieces of gold from the impurities. The impurities should be swept off the paper and the gold should be poured into a gold sample bottle. This is where a funnel comes in handy.

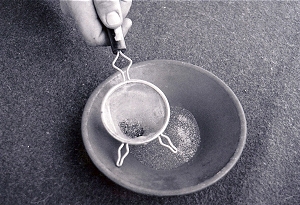

STEP 4: Once the larger-sized concentrates have been separated, the remaining concentrates can be classified through a finer-mesh screen. A stainless steel, fine tea strainer (about 20-mesh) works well for this. Tea strainers can be found in just about any grocery store.

STEP 5: Take the larger classification of concentrates from the second screening, pour them onto a clean sheet of paper, and separate the gold from the impurities in the same way that it was done with the larger material in Step 3 above.

Use of a magnet on each size-classification of concentrates can be very helpful to remove those impurities which are magnetic.

Some prefer to use a fine painter’s brush to separate out the non-magnetic impurities. Separation can also be accomplished by using your fingers. This step goes faster if you only do small amounts of concentrate at a time. Pour the gold recovered in this step into the gold sample bottle.

STEP 6: Take the fine concentrates which passed through the final screening and spread them out over a clean sheet of paper. Use a magnet to separate the magnetic black sands from these final concentrates. The magnetic black sands should be dropped onto another sheet of clean paper, spread out, and then gone through with the magnet at least one more time. The reason for this is that some gold can be carried off with the magnetic black sands. They tend to clump together. Once the magnetic black sands have been thoroughly separated from the gold to your satisfaction, pour them into your black sand collection. There may still be some small gold values left with them which can be recovered by other methods at another time.

NOTE: There is a really nice set of final clean-up screens on the market that are made just for the purpose of separating your final concentrates into the ideal size-fractions for final dry separation. I highly recommend them, because they separate your final material into multiple size classifications which make the final dry process go even faster.

STEP 7: Now, all that should be left is your fine gold, possibly some platinum, and a small amount of non-magnetic black sand. These final black sands can be separated by blowing lightly over them while vibrating the sheet of paper. Since the sand is about 4 times lighter than the gold, it will blow off the paper a little at a time, leaving the gold behind. Once all the black sands are gone, you can pick out the pieces of platinum if present, and separate them from the gold. Pour the gold into the same gold sample jar used in the earlier steps.

This dry process (Steps 1-7) goes very quickly if an effort was made during the final wet stages to get as much black sand and other waste material as possible separated from the gold.

CLEANING GOLD

Sometimes placer gold just out of a streambed is very clean and shiny. If this is the case with your gold, after the final dry cleanup procedure is completed, your gold is ready to be weighed and sold or displayed or stored away in a safe place.

Sometimes, gold will come out of a streambed with some impurities attached to it. When this happens, it will be necessary to perform a final cleaning process to make the gold’s natural beauty stand out.

If your gold is not clean and shiny, and you want to get it that way, place it in a small non-breakable water-tight jar about half full of water and add a little dishwashing liquid. It does not seem to matter what kind is used. Fasten the top on the jar and shake the contents vigorously until the gold changes to somewhat of an unnatural glittery color. Sometimes this happens quickly and sometimes it takes a little longer. This mostly depends upon how much gold is in the jar. The more gold, the faster the process. This is because it is the friction of gold against gold which facilitates the cleaning process. Once the gold is glittery, rinse the soapy water out of the jar, pour the gold into a small (metal) finishing pan, and heat it up (outside and down wind) until the gold takes on a deep, natural, shiny luster. It is important to make sure that all of the soap has been rinsed away from the gold using clean water before you dry the gold.

Gold has a tendency to turn a dull color after having been stored in an airtight container for an extended period of time. For this reason, some gold miners and dealers store their gold in water-filled jars, and dry it out just before displaying it or making a sale.

If you should happen to store your gold in an airtight container and notice that its color does not seem to be as bright as it once was, wash it with soap and water and re-heat it, as in the above steps. This process will bring back the beautiful color and luster of the gold.

The best time to weigh your gold to get the most accurate measurement is after you have completed all of the final cleanup steps.

SELLING GOLD

There are numerous markets where you can sell your gold. Refineries will pay you for the fineness (purity) of the gold itself and subtract a few percent for refining charges. In this case, you will receive a little less than the actual value of the gold. Refineries usually will not pay for the silver and platinum contained within your placer gold unless you are delivering it in large quantities. Refineries prefer that you bring your gold to them in large amounts. They will often charge less for refining, and sometimes pay just a bit more for the gold, when it is brought to them in larger quantities.

There are numerous markets where you can sell your gold. Refineries will pay you for the fineness (purity) of the gold itself and subtract a few percent for refining charges. In this case, you will receive a little less than the actual value of the gold. Refineries usually will not pay for the silver and platinum contained within your placer gold unless you are delivering it in large quantities. Refineries prefer that you bring your gold to them in large amounts. They will often charge less for refining, and sometimes pay just a bit more for the gold, when it is brought to them in larger quantities.

Flakes of gold and nuggets have jewelry value on a different market. If marketed to the right buyers, flakes and nuggets can usually bring in more than a refinery will pay-or sometimes even much more.

If you are in gold country and ask around, you can nearly always find someone who is buying placer gold from the local miners. These individuals usually pay cash. Unless the fineness of the gold within the area is lower than normal, there is no reason to settle for less than 70% of the market-value of the gold for that day. This means that the gold is weighed and the buyer pays you for the weight of what you deliver. Impurities are never calculated into this type of deal. If you enquire around, you can usually find someone who is willing to pay 75% of weight. Sometimes you can find an 80% straight-out buyer-which is good.

There are also people out there who are ready to gyp you out of your gold if they can get away with it. It is wise to bring your own pocket calculator along when dealing with a new buyer.

If you go to a dealer who starts figuring a certain percentage of the fineness, and his final figures end up lower than a straight out 70% of the bulk weight of your gold as it is, go find another dealer. This is not to say that 70% is the going rate. You can do better if you look around. Although, you should never have to accept less than 70% of the going market price for your gold. If a dealer starts to tell you all sorts of reasons why your gold is not worth what you want for it, go find someone else. There are plenty of gold buyers around who will at least admire your gold. So there is no reason to hang around and listen to someone who is trying to steal it from you.

Local miners will know who pays the most! Or go up on our web forum and ask. Someone there is sure to turn you onto a good deal!

Cleaning your gold well before you take it somewhere to be sold can help a lot.

Sometimes dentists will give you a good price for your gold, and a phone call or two can pay off. Also, some lawyers and businessmen like to invest in gold. Sometimes you can get up to 100% of spot for your fines (fine gold) when dealing with them.

Some jewelers will pay well for your flakes when they have a demand for them. It is not uncommon to get as much as 90% or better when you make such contacts.

The best way to get top dollar for your gold is to do a lot of inquiring, always with the intention to find more and better markets. Then, when you need some cash, you can sell to the buyer who pays the most.