Quite often in gold mining, your best-laid plans fall completely apart as soon as you get started. This happens to me on a regular basis. In late August, we had a firm plan to do a week-long dredging project on our Lower Seiad Claim (K-14). I know of a place there that should deliver up a substantial high-grade gold deposit. But the day before we were to start, a large truck drove off the highway and spilled some kind of oil into the Klamath River. Not wanting to take any chances of exposing our team to the possibility of hazardous material, we decided at the last minute that we needed to do our dredging project upstream from the oil spill. So we went up to UK-3. Through just several hours of sampling, we got right into a rich pay-streak up there. Everything turned out alright in the end. I suppose the lesson in this is that in prospecting, you just have to adjust yourself to setbacks when they happen and keep on moving forward.

Then, since we had not finished up the rich deposit that we found on UK-3 in August, we were planning to go back in there on our September group dredging project and pick up right where we left off. It is a lot of stress off my shoulders to begin a dredging project in an already-established pay-streak. This allows me to put more of my personal focus on working with the project participants. Out of the 15 people associated with the September project, 9 of them had never even breathed off a hookah-air system before. Wow; that is a lot of beginners to get grooved into an underwater program all at once! So already having an established high-grade gold deposit in place meant that we would not have to sample. This was good!

As these group projects only last a week, and the first and last days are mostly devoted to orientation, moving gear on and off the river and final gold clean-up, there really are only 5 production days to make the gold add up. Making the gold add up is important to the last day when it is time to split it off amongst all the participants. I know this better than anyone, because I am the one that weighs and splits each share. The bigger the share, the better it feels when you get it! So every day matters to the final outcome!

It is also true that a beginner who is worried about drowning in the river does not care very much at that moment about how much gold is being recovered. That person just wants to stay alive!

It is also true that a beginner who is worried about drowning in the river does not care very much at that moment about how much gold is being recovered. That person just wants to stay alive!

I devote a lot of the season helping beginners through the early stages of underwater mining. So I have an intimate understanding of the different feelings and motivations.

First of all, I just want to say that everyone has a primal fear of drowning. It’s really a matter of how energized that fear is at the moment. I’m a strong swimmer and spend a lot of my time around the water. So I am reasonably comfortable under normal (for me) circumstances. But when I tried surfing several years ago in Maui, and found myself tumbling head-over-heals along the underside of a big wave, I immediately tuned into a panicked madman fighting for my own life. It didn’t feel like I was going to live through it! After that, I was afraid every time I tried to catch a wave. Numerous times when I really had the opportunity to catch a great wave, I chickened-out and decided not to go for it. I never did learn to surf very well. I’m afraid! So it is easy for me to identify with the fear that others experience around the water. That fear is very serious stuff!

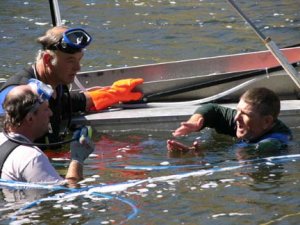

Many beginning participants on these group dredging projects arrive with a healthy fear of the water. Some have had earlier traumatic experiences. Some were born with fear of the water. Some just have a healthy respect. With 9 beginners in this project, I knew that a lot of my personal focus would need to be devoted to helping them get through the beginning steps of dredging.

Just for the record, these group mining projects are not a school or a class. They are joint mining ventures where all participants work together as a team to locate high-grade gold deposits and recover as much gold as we can out of them by the end of the week. Those that are not able to contribute to the underwater work are utilized in other activities on the surface to help with forward momentum. Those that do not know how to do the underwater activity, but who wish to contribute there, are helped through the beginning stages so they can become more productive to the group venture. Everyone (including me) learns something on every mining project. I’m sure that is true of any type of activity where a person is personally challenged. As the project manager, without compromising safety, my personal job is to get as much productive activity as I possibly can out of each member of the team. More productive activity channeled in the right direction will produce more gold by the end of the week. This makes everyone happy with the final result.

Showing someone how to get comfortably underwater during the first few days of a dredging project means that we will have yet another person helping us to recover high-grade gold later in the week. Therefore, my plan on this project was to direct our 5 more-experienced participants to get started in the established pay-streak right away, while I invested my time working with the beginners. This way, we would be accumulating gold from the very beginning. That is always a great way to start!

And here is just one more example (of many) of how a great mining plan fell apart even before we got started: We arrived on UK-3 on Saturday afternoon, only to discover that the Iron Gate Dam had increased its water release that very same morning, causing the river to rise about 18 inches in the section of river where we had intended to dredge. This made the water flow there too fast for us to dredge! So much for that plan!

One thing I have learned is that dwelling on problems or failures does nothing to increase the size of gold shares at the end of a project. So after allowing myself just a brief moment of personal disappointment in the realization that we would need to find another high-grade gold deposit with just 5 people, our newly-formed team did a complete survey of the UK claims in search of a new place to begin a sampling program.

The river was running higher and faster. So our options were actually reduced to just several locations. Each of these looked pretty good. As a group, we always allow some time to discuss each option. There is often some debate on these matters, but I must ultimately make the final decision. This time, we decided to go down to the upper part of UK-2. Mainly, this was because we had left some high-grade gold behind there during an earlier dredging project (last season). In addition, longtime supportive member, Lee Kracher, happened by at just the right moment and told us that his son had been pulling a lot of gold out of the river not far downstream from where we had already mined some high-grade along the upper portion of UK-2. I assumed this was probably an extension of the very same deposit we had been mining the year before. As Lee said his son was pulling out gold through the last day of his vacation, this area seemed pretty-much like a sure thing for our project.

I always go for the most sure thing I can find when results really matter! Our new plan required us to work until dark on the first day to get all of our dredging gear moved to our new project site.

Luckily, Craig Colt and Jason Inks were along to give us a hand on this project. Both have extensive experience in serious dredging and team management. We split up our experienced participants into two teams on the morning of the second day; with Craig’s team operating the 8-inch dredge, and Jason’s team operating the 6-inch dredge.

Because every day counts, we set realistic targets every morning. These are the things that we must accomplish to ultimately achieve our objective (plenty of gold) by the end of the week. Craig’s and Jason’s targets on Sunday were to both get their teams established in the pay-streak before the end of the day. We positioned their dredges downstream of where we had been dredging high-grade last season and they didn’t waste any time getting started.

Then we set up a 5-inch dredge just off a shallow sand beach where I could work with the beginners. I always begin with those who seem like they will get through the initial steps quickly. Those persons are then directed to operate the 5-inch dredge as part of the ongoing sampling program, while I work with the participants who will require more time along the edge of the river. As soon as they demonstrate that they are up to it, some beginners graduate off to help on one of the other dredges where they can be more productive. By more productive, I mean that a good sampling program requires that we do sample holes out into the deeper, more challenging parts of the river. Sometimes, this is where the richest gold deposits are found. Sampling for high-grade is a lot like playing hide-and-seek. You have to be prepared to go anywhere the deposits might be located.

Starting into the third day, both of our serious dredges were pushing out further towards the middle of the river. While they were finding some gold and small nuggets in closer to the bank, we believed the gold was going to get better as we moved further out. It did, but it still was not as good as we wanted. So we decided to move the 6-inch dredge further upstream, closer to the area where we were mining rich gold the season before. By trial and error, we just kept up the process of doing small dredge samples here and there and checking the results to trace the gold into the richer portion of the pay-streak. The following video was captured just as Jason’s team was starting to uncover what we were looking for:

Shortly thereafter, Jason’s team started expressing the excitement of seeing gold while uncovering bedrock on the river-bottom. In other words, they were hooping and hollering it up pretty good. This is always a good sign to me that things are moving in the right direction.

“The first nuggets started coming up after we moved the 6-inch dredge further upriver”

By the end of the third day, all of our beginners (except for one person who insisted from the beginning that he was not going underwater) were through the initial learning curve and being productive underwater. So we moved the 5-inch dredge just upstream of Jason’s team, and they immediately also started uncovering high-grade gold along the bedrock. Everybody started getting pretty excited!

There is nothing quite like seeing gold nuggets on the bottom of the river to help a person get over their initial fear of the river! I’m serious! It is always good to try and get a beginner extroverted. A good way to do that is to get the person helping to uncover high-grade gold from the bottom of the river!

Some participants arrive on these projects with deep-seated fears or phobias of the water. Some participate with the hope of overcoming these fears. Others arrive with no intention of going underwater; they just want to help on the surface. This is alright with me. We talk this all over as a group on the first day, and always then move forward with an understanding that everyone will just participate the best that they can to help get the job done. It is important to get the right kind of team chemistry in place on the first day. Working together with a good team, so far, we have always managed to locate high-grade gold.

Interestingly, everyone I have worked with that has started out with a serious fear of the water goes through very similar stages as the fear is overcome. I always just start the person out doing something that he or she is comfortable with – like just sitting or standing alongside the river without a face mask, getting used to breathing through a hookah regulator. Sometimes this first step is the most difficult in the whole chain of progressive steps! It is not unusual for someone’s body initially to reject having a regulator in his or her mouth (creates an impulse to gag it out). Still, a person standing up on the bank has little to fear from putting the regulator back and trying to breathe from it some more. Amazingly, the body always makes its own adjustment about this rather quickly all on its own. It is not a mind process. Thinking or talking about it does not seem to help very much with the process. The answer is to just keep the regulator in the person’s mouth until it is no big deal anymore. This usually happens pretty fast if the person just does it.

The next step is to have a person just get comfortable wearing a face mask. Sometimes we start out with this step before the regulator. It doesn’t really matter. But, if we are trying to overcome a healthy fear, we always do these two steps by themselves, before we ask the person to wear the face mask and breathe through the regulator both at the same time. It is just a simple matter of taking things one step at a time. No big deal. This all plays out alongside the edge of the river, while the bigger sampling program out in the river is being moved forward by the more experienced participants

Everyone has a threshold where traumatic fear overcomes everything else. This is commonly referred to as “panic.” That’s the place where you lose personal control and totally freak out! Water can bring that threshold very close to the surface with some beginning dredgers. I have worked with so many people on this over the years that I have developed an intimate sensitivity to what people are going through. The important key is to avoid pushing someone beyond his or her personal threshold of fear.

The step-by-step routine works every time. Most of the process is just to get the person’s body accustomed to being in a different environment. That’s all.

Once the person can breathe comfortably through the hookah regulator while looking through the face mask (even while standing or sitting alongside the river), the person has already made it well beyond the half-way point in getting comfortable underwater.

This all gently progresses to having the person float around in shallow water along the edge of the river while looking underwater through the mask and breathing through the regulator. Here is another milestone in the program, because the body initially doesn’t believe that it can breathe with your face in the water. Again, the key is just to do it!

The internal fear almost always presents itself in discussions, like “I have never been a mouth-breather.” I have found that discussions usually do not help very much with the progress. So I just coax the person to just keep putting his or her head in the water as much as he or she can tolerate until the body makes an internal adjustment. Initially, the person never believes that the body will adjust. That is just part of the internal fear being expressed. The body always adjusts just by doing it. It usually happens very fast. Because personal embarrassment also comes out with the fear, I usually back off a bit and just allow the person to work through this on his or her own. I usually only step in when I see the person is not continuing to put his or her face in the water. That’s the key. In 25 years of helping beginners, I have never seen a time when the person did not get through this step very quickly, as long as the person just stuck with it.

Usually, within just a short time, the person is swimming around comfortably while looking around at the fish, or watching the dredging program if it is close enough to be seen. That’s when I go over and gently press the person underwater. This step is always done in shallow-enough water that the person can push his or her head above the water’s surface if he or she feels the need to do so. They almost never do, though. By now, the person is already through most of the fear. This is relatively an easy step in the progress.

Then I straddle a set of weights across the person’s back to let him or her sink to the bottom in shallow water. This is also an easy step, because the person always finds that he or she has more personal control with the weight, than when I am holding him or her down. Soon thereafter, I buckle the weights onto the person to keep them from slipping off. The person has now comfortably made it to the bottom of the river. It’s not so difficult as long as we don’t try to move things along too fast and overstep beyond the person’s fear threshold.

In dredging, it is important to be weighted heavily to the bottom of the waterway. But the heavy weights usually make a person a bit top-heavy. Because of this, you cannot swim or walk around very effectively. The right way is to crab around on the bottom using your hands and legs. Balance is everything.

The final step in the process of helping a beginner is always to have the person go underwater and roll over onto his or her back, and then roll back over again. We do this several times. About the worst thing that can happen is that you lose your balance and roll onto your back like a turtle. So, in shallow water, we just get the person to do this right away and get it over with! I am always standing right there with the person’s hookah line in hand – more for moral support than anything else. Once a person has rolled around on the bottom of the river a few times, the body will automatically learn how to maintain its own balance. From there, the rest is pretty easy.

Until the person as demonstrated an acceptable level of personal confidence, we usually have someone keep a firm grip on his or her hookah airline just for safety. Although, to date, I have never actually had to drag anyone in by their airline.

Really, it is amazing how fast people adjust to the underwater environment! Most people have more courage than they allow themselves credit for. The following video sequence was captured while several of our beginners were working through the process:

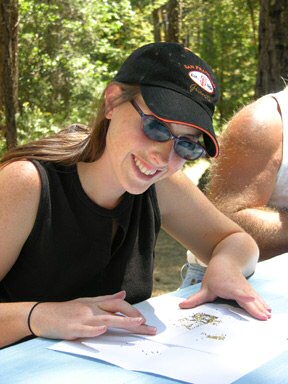

Out of our 9 beginners on this project, the 4 woman got through the initial learning curve surprisingly fast. This was probably because they were giving each other a lot of assistance and moral support. By mid-week, we had woman dredgers helping with an important portion of the underwater work on both the 5 and 6-inch dredges. The following video was captured just as the two dredges were beginning to recover high-grade gold:

Everyone was so excited about it, on the 5th day; even the guy who insisted that he would never go underwater decided he wanted to give it a try. As he had spent so much time watching the others learn how to do it, it only took him about an hour to get underwater. Now 100% of our dredging team was working in the water.

While we had both the 5 and 6-inch dredges into high-grade on the third day, we could not set up the 8-inch dredge there because of the way the river was flowing in that particular location. There simply wasn’t enough room. That was too bad, because the 8-inch dredge will process more stream-bottom than the 5 and 6-inch dredges combined. This is especially true when Craig Colt is operating the suction nozzle!

Craig’s team pushed their downstream sampling program further out beyond the middle of the river in search of high-grade. But they still had not struck the pay-dirt that we were looking for. In a sampling program, if what you are doing is not producing adequate results, you try something else. And you just keep trying different things until you find something good. The problem here was that we only had several days to make it all happen. We were running out of days!

So once all of our beginners were safely established underwater, I personally took on the mission of locating the dredge excavation which Lee Kracher’s son had made earlier in the season. Nobody was quite sure where that was. We could not see where it was from the surface of the river. Lee had pointed downstream and across the river. That’s all we knew. Since they had recovered high-grade from that location, our plan was to move the 8-inch dredge over there for our next sample. We were feeling a strong need to do something effective, and soon!

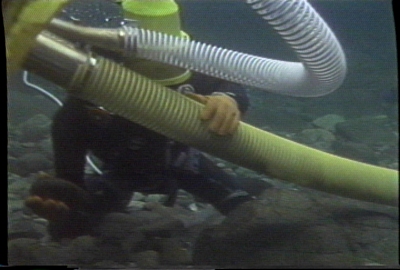

I take the opportunity to do a lot of underwater prospecting during these projects. By this, I mean swimming around underwater to have a look at what is on the bottom. It’s the only way I know of to see what is down there! By doing a survey of the bottom, I can see where the bedrock is visible and what it looks like. Seeing exposed bedrock will allow our team to dredge samples nearby without having to go through deep streambed material (which takes more time and effort).

Surveying the river-bottom also allows us to discover where the hard-packed natural streambed is and where the boulders are. It also allows us to see where others have dredged before. I almost always swim around and survey the bottom of the river before deciding where we will dredge sample holes.

There are two ways I know of to survey the bottom of the river. One is to put a long extension of air line on your dredge’s hookah air system; like about 200 feet. Then, with your weights on, you can survey a big area around where your dredge is floating.

The other way is to float with the flow of the river, diving down on single breaths of air, to get a look at the bottom. Doing this without a wet-suit makes it easier to get down to the bottom and stay there longer. While you cannot stay down very long on a single breath of air, not being connected to anything allows you the freedom to survey long stretches of river.

Depending upon the circumstances, sometimes we float long stretches of river holding onto the bowline of my boat, just drifting along with the flow. It’s amazing how much you can discover about a stretch of river just by swimming it a few times! The following video sequence was captured while I scanned the river-bottom of UK-2 looking for that pre-existing dredge hole that Lee told us about:

It just took a little while for me to find the excavation which Lee’s son had left behind. While swimming along, I just kept looking for a dredge hole, a cobble pile or the tailings. I spotted the cobbles first. This turned out to be big hole; Lee’s son had done a lot of work! Fortunately, the excavation was just as he left it. He had been dredging in about 5 feet of original hard-packed, gray-colored Klamath river-bottom material. There were some large boulders visible. It would have taken us the better part of a full day or longer just to open up a good sample in this same location using the 8-inch dredge. Luck was on our side that someone else had already accomplished all that work for us and made the gold discovery there. It was going to be easy for us to go right into production in this hole!

This is one of the great things about being a member of The New 49’ers; it seems like someone is always coming along and letting you in on some already existing, exciting opportunity!

To save time, we just put the 8-inch dredge nozzle in the front of the boat, and I reverse-motored the whole platform across the river. This is a common way for us to move a dredge around when sampling in slower-moving water. Once to the other side of the river, all we had to do is tie the dredge off and go to work. The following video segment shows how we transferred the whole 8-inch dredge program from one side of the river to the other:

Two hours later, we had our first high-grade clean-up on the 8-inch dredge. The following 2 video segments were able to capture some of the excitement (and relief) we all felt when we finally got the 8-inch dredge into high-grade gold:

By Wednesday afternoon, all three dredges were in high-grade gold and all of our beginners were helping push underwater production forward. That sure was a long way from where we began at the beginning of the week!

As is normal, there was not much for me to do on Thursday. Our whole group had already pulled together as a polished team. Everyone already knew everything that needed to be done. Those that were so frightened of the river early in the week had long-since evolved into experienced gold dredgers who were working together with the team to recover as much gold as we could in the time remaining to us. I could have taken the day off and probably nobody would have even noticed! I always find myself feeling a bit helpless towards the end of these projects when everyone else is doing all the work and there is little for me to do.

Because so much time is required to do the whole process, we always accumulate our concentrates in a bucket throughout the week and do the full gold clean-up on the final day. We also needed to pull all of our dredging gear off the river this time, because it was the end of our dredging season along the upper Klamath River. We all worked together on this. Fortunately, there are several river access points down towards the lower-end of UK-2. We used the boat to tow all 3 dredges down there. Then we used the electric winch mounted in the back of my truck to load the dredges on trailers, tie them down and hoist them up to the road. Even the 8-inch dredge came up the hill without a single hitch! The following video sequence captured how smoothly the whole process went:

“Dave Beatson from New Zealand”

“Dave Beatson from New Zealand”

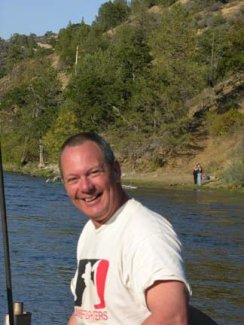

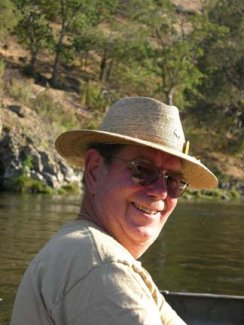

We often have visitors in Happy Camp from other countries. This time, we were honored with the presence of David Beatson, who is a very enthusiastic gold prospector from New Zealand. David is one of those rare individuals that always adds more life and fun to the party. He also carries a big part of the work load! It was interesting to listen to David talk about his gold mining adventures in New Zealand. There is a common bond created amongst gold miners that cannot be duplicated in most other types of endeavors. Here follows some of what David had to say:

This season, we were also rewarded with the presence of Otto Gather on all of the group projects. We call Otto “Mister Mom,” because everyone  looks to him to provide all of the important basic necessities, whether it is a cup of coffee in the morning, fuel to keep the dredges operating, a spare part, a Band-Aid, or even a spanking if you deserve one. I’m not talking about anything kinky here. Otto has a kind way of telling a person to quit being a sissy just at the time you need to hear it! He adds much-needed life and substance to these projects that make them better for everyone.

looks to him to provide all of the important basic necessities, whether it is a cup of coffee in the morning, fuel to keep the dredges operating, a spare part, a Band-Aid, or even a spanking if you deserve one. I’m not talking about anything kinky here. Otto has a kind way of telling a person to quit being a sissy just at the time you need to hear it! He adds much-needed life and substance to these projects that make them better for everyone.

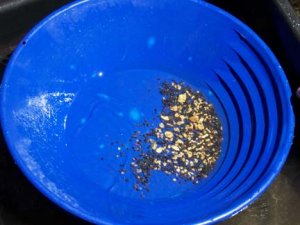

Final clean-up was finished in camp on late Friday afternoon. All participants are always encouraged to participate in the final clean-up. Because we accumulate so much gold, there is actually quite a lot of work involved! The following video sequence captured the highlights of the full process which we normally follow:

“Otto Gather provided a lot of help on this year’s group mining projects!”

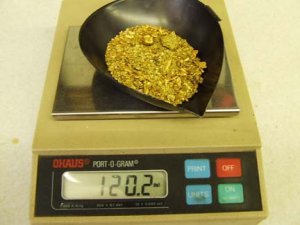

Altogether for the week, we recovered 118.4 pennyweights (5.92 ounces) of beautiful gold. That included 27 pennyweights of very nice nuggets to go around. Everyone was pleased with the result, and we all said our goodbyes before going our separate ways. This was the end of another very special chapter in each of our lives.

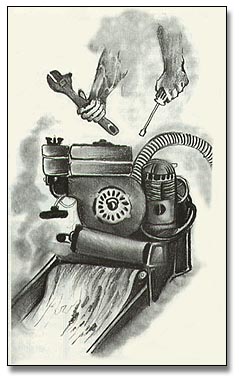

wrench, or a clamp, only to find the store just closed! Make up a small kit of tools and parts to keep with the mining equipment.

wrench, or a clamp, only to find the store just closed! Make up a small kit of tools and parts to keep with the mining equipment.

One of the main impediments to production in

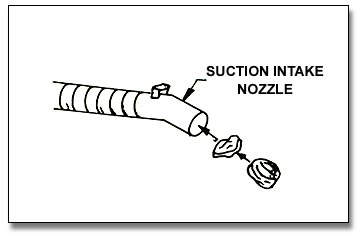

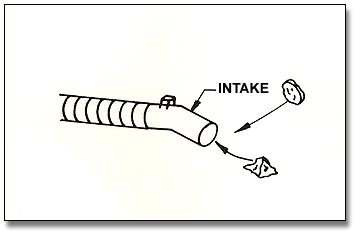

One of the main impediments to production in  Many plug-ups occur in the power jet. These are generally caused for two reasons (in addition to sucking up the wrong rocks). The first is because of a design-flaw. Many power jets are smaller in diameter than the inside of the suction hose. Where the larger-sized suction hose meets the smaller-sized jet, there is a restriction which can cause rocks to lodge.

Many plug-ups occur in the power jet. These are generally caused for two reasons (in addition to sucking up the wrong rocks). The first is because of a design-flaw. Many power jets are smaller in diameter than the inside of the suction hose. Where the larger-sized suction hose meets the smaller-sized jet, there is a restriction which can cause rocks to lodge.

All of this unnecessary additional work will prompt you to pay more attention to what you are feeding into the nozzle! I have spent plenty of time watching beginners invest more than 50% of their day just on freeing plug-ups!

All of this unnecessary additional work will prompt you to pay more attention to what you are feeding into the nozzle! I have spent plenty of time watching beginners invest more than 50% of their day just on freeing plug-ups!

It is also true that a beginner who is worried about drowning in the river does

It is also true that a beginner who is worried about drowning in the river does

“Dave Beatson from New Zealand”

“Dave Beatson from New Zealand” looks to him to provide all of the important basic necessities, whether it is a cup of coffee in the morning, fuel to keep the dredges operating, a spare part, a Band-Aid, or even a spanking if you deserve one. I’m not talking about anything kinky here. Otto has a kind way of telling a person to quit being a sissy just at the time you need to hear it! He adds much-needed life and substance to these projects that make them better for everyone.

looks to him to provide all of the important basic necessities, whether it is a cup of coffee in the morning, fuel to keep the dredges operating, a spare part, a Band-Aid, or even a spanking if you deserve one. I’m not talking about anything kinky here. Otto has a kind way of telling a person to quit being a sissy just at the time you need to hear it! He adds much-needed life and substance to these projects that make them better for everyone.

The first thing we do is set up a camping area where we can have our planning sessions each morning.

The first thing we do is set up a camping area where we can have our planning sessions each morning.

This was a very easy location where beginners could learn!

This was a very easy location where beginners could learn! The 6-inch dredge was drifted across the river to dredge some samples on the other side. This, because some members had reported several years ago that they were finding nice gold over there mixed with pieces of metal from some kind of old Chinese camp. This all took place at the top end of K-15A. But we were not able to find hard-pack streambed on the far side of the river, and did not want to invest very much time over there since we were doing so well on the road-side. One hard effort was made to dredge a sample in the middle of the river, but we gave up when the loose streambed material reached around 6 feet deep.

The 6-inch dredge was drifted across the river to dredge some samples on the other side. This, because some members had reported several years ago that they were finding nice gold over there mixed with pieces of metal from some kind of old Chinese camp. This all took place at the top end of K-15A. But we were not able to find hard-pack streambed on the far side of the river, and did not want to invest very much time over there since we were doing so well on the road-side. One hard effort was made to dredge a sample in the middle of the river, but we gave up when the loose streambed material reached around 6 feet deep.

The main problem we were facing early in the week was that the Klamath River was still flowing abnormally high because of the record amounts of rain we had last winter. High (fast) water was making it nearly impossible for us to complete sample holes out in the middle of the river.

The main problem we were facing early in the week was that the Klamath River was still flowing abnormally high because of the record amounts of rain we had last winter. High (fast) water was making it nearly impossible for us to complete sample holes out in the middle of the river. We place a lot of attention with the beginners during the first day or two of these Projects. The idea is to help them through the initial steps so that they can become more productive participants in the ongoing sampling and productive aspects of the bigger program. Beginners are graduated to more advanced work as the days go by and the sampling program evolves. All of the effort combines to a very effective mining program.

We place a lot of attention with the beginners during the first day or two of these Projects. The idea is to help them through the initial steps so that they can become more productive participants in the ongoing sampling and productive aspects of the bigger program. Beginners are graduated to more advanced work as the days go by and the sampling program evolves. All of the effort combines to a very effective mining program.

Our 4th dredge team on this Project was being managed by Rick LaRouque. Rick was joined by several other moderately-experienced dredgers. But these were some

Our 4th dredge team on this Project was being managed by Rick LaRouque. Rick was joined by several other moderately-experienced dredgers. But these were some

The thing about high-grade is that when you uncover it, the

The thing about high-grade is that when you uncover it, the  The 6th day of the Project found our whole company eager to get an early start on the river. The first thing we did was float Jake’s dredge and team downstream to fall-in alongside the A-team. It did not take very long for the teams to get both dredges into

The 6th day of the Project found our whole company eager to get an early start on the river. The first thing we did was float Jake’s dredge and team downstream to fall-in alongside the A-team. It did not take very long for the teams to get both dredges into  Most of these people did not even know each other only 6 days before. Yet, here they were on the river working together as an experienced team of prospectors who had overcome all of the unknowns that we began with, worked their way together through some pretty difficult conditions, kept the faith throughout the whole process, and pulled off a

Most of these people did not even know each other only 6 days before. Yet, here they were on the river working together as an experienced team of prospectors who had overcome all of the unknowns that we began with, worked their way together through some pretty difficult conditions, kept the faith throughout the whole process, and pulled off a

Three of the participants were

Three of the participants were

By the end of the third day, our remaining three people on the beginner-team were managing the second 4-inch dredge all by themselves, and had launched into

By the end of the third day, our remaining three people on the beginner-team were managing the second 4-inch dredge all by themselves, and had launched into

Meanwhile, Ken’s team on the other side of the river decided to dredge a hole down through the hard-pack to see if they could find bottom. They found it at a depth of around four feet in the gray-pack. With even more luck on our side, through some trial and error, they discovered that in addition to the surface gold deposit, the gray layer of hard-pack was also paying consistently in fine gold and flakes throughout the material. Then they found the largest nugget of the week on the fourth day. So they devoted the remainder of the week production-dredging to the bottom.

Meanwhile, Ken’s team on the other side of the river decided to dredge a hole down through the hard-pack to see if they could find bottom. They found it at a depth of around four feet in the gray-pack. With even more luck on our side, through some trial and error, they discovered that in addition to the surface gold deposit, the gray layer of hard-pack was also paying consistently in fine gold and flakes throughout the material. Then they found the largest nugget of the week on the fourth day. So they devoted the remainder of the week production-dredging to the bottom. Also, it appears to me that we are attracting more experienced miners to the Projects. This increased experience helps focus the Projects in a more productive direction.

Also, it appears to me that we are attracting more experienced miners to the Projects. This increased experience helps focus the Projects in a more productive direction.

Herb Miller and Doti Buruursema prepare to start a sample hole on the far side of the river.

Herb Miller and Doti Buruursema prepare to start a sample hole on the far side of the river. Sandy Crawford always ready to light up the day with a big smile.

Sandy Crawford always ready to light up the day with a big smile.

We never use mercury or any chemicals in the process. It is important for every prospector to know how to do the final gold separation. On our projects, under my careful guidance, the participants do almost all of the work. But I always get the personal pleasure of weighing out all the final shares.

We never use mercury or any chemicals in the process. It is important for every prospector to know how to do the final gold separation. On our projects, under my careful guidance, the participants do almost all of the work. But I always get the personal pleasure of weighing out all the final shares.